- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

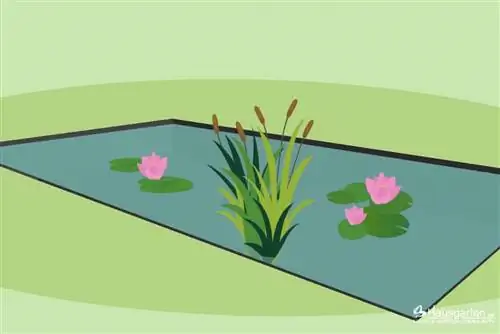

GRP is considered a versatile and high-performance material composite for a wide variety of applications. Known from boats, containers and sometimes even automobiles, it offers excellent properties for creating a pond that is durable and stable. For all those hobby gardeners and pond lovers who would like to create their own pond bowl, we offer helpful tips on working with fiberglass mats and resin.

What is GRP?

In order to be able to classify and understand the following tips correctly, you should first keep in mind what the GRP composite material is all about and what the letters that give it its name actually stand for.

NOTE:

Often translated directly as glass fiber reinforced plastic, the abbreviation actually describes a word creation from the English “glass fiber” and the German “Kunststoff”. The underlying statement is the same, but when translated literally into the German term it is a so-called “false friend”.

The material consists of two essential components: glass fibers and synthetic resin. Both materials together create a material composite that is tough, impact- and shock-resistant and can withstand heavy multidirectional stress. Common materials used are:

As glass fibers:

- Glass fabric

- Fiberglass mats

As resin:

- Polyester resin

- Epoxy resin

The shaping is done by positioning the glass fibers, which can later be laminated with the resin. Depending on stability, shape, etc., a multi-layer structure may be necessary.

Tips for glass fiber reinforced plastic when building a pond

Now that we know again which material to work with, it's time to move on to practical tips for making the pond bowl easier, safer and more reliable:

He alth protection

Mostly perceived as annoying, occupational safety and therefore direct he alth protection are of great importance when processing glass fibers and synthetic resins. The reason for this is the amount of materials that have to be processed in a pond, as well as the effects on the human organism that can arise from the components themselves:

- Skin irritation caused by components of the synthetic resins, such as solvents, binding agents, etc.

- Corrosions of the respiratory tract caused by solvent vapors

- Skin irritation due to released glass fibers

- Permanent damage to the eyes caused by glass particles

- Difficulty breathing, temporary or permanent, due to inhaled fiberglass

It is therefore important to take appropriate protective measures to protect against these same effects:

- Protective glasses for all work

- Protective gloves for all work, for work with resins if necessary solvent-resistant

- Mask protection for working with glass fibers, such as cutting, grinding etc.

- Adequate ventilation of the work areas due to. Exhalations

- Avoid open flames, e.g. cigarettes etc., due to flammable components

ATTENTION:

The possible he alth impairments should not be neglected, even if it is “only” one-off work. The damage caused often only becomes apparent as long-term consequences many years or decades in the future. The specific work does not always cause impairments. Instead, they contribute to a possible clinical picture with other aspects.

Choosing the right materials

As already described, glass fiber reinforced plastic can be laminated from different components. The following two material combinations are common:

- Epoxy resin + glass fabric

- Polyester resin + glass mats

For a pond, the combination of polyester resin and glass mats is clearly recommended. This material mix brings with it some clearly advantageous conditions for pond construction, which clearly sets it apart from the alternative:

- Easy processing of components

- Fast curing of the resin

- Significantly cheaper than epoxy resin and glass fabric

- High longevity

NOTE:

In contrast to polyester resin, epoxy resin is also available solvent-free. Since work on ponds usually takes place outdoors, this advantage is unlikely to outweigh the disadvantages compared to the alternative.

Conscientious work instead of time-consuming rework

To be honest, laminating glass fibers using synthetic resin will hardly be possible without sanding. The reason for this is:

- Mat edges and corners

- Protruding glass fibers and fiber bundles

- Grains of sand, stones and other foreign bodies

- Uneven surfaces

This raised surface must be removed by sanding both before laminating the subsequent layers and before the final coating. Since this process is always associated with dust and glass particles, as well as noise, dirt and effort in general, avoidable causes should be prevented as far as possible. This is achieved through careful and conscientious work. In detail you should

- Lay mats without kinks or wrinkles

- keep the work area clean

- Arrange work on wind-free days

- If applicable. vacuum the tissue again before applying the resin

Material mix for better results

There are different properties of the glass mats for every application. For high load capacities these are coarse, thick mats, for finer shapes they are softer mats with a thinner cross section. To improve the work results, these different products can also be combined:

- Thick glass mats for the forming layer of the pond

- Thin glass mats as a top layer with a smoother surface

- Medium-thick mats to reinforce the top layer at critical points, such as possible streams or striking shapes

In the end, higher material thicknesses may be created through additional layers, but the effort for post-processing can be significantly reduced.

Pigments as sun protection

Whether installed above or below water, synthetic resin and glass fabric age when exposed to heat, cold and, above all, UV radiation. While heat and cold protection is already achieved by the pond water, premature aging can only be prevented by shielding the material from harmful light waves with a protective layer. This protection can be achieved through a combination of two measures:

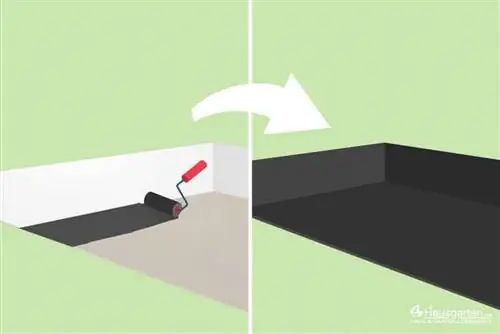

- Coloring the resin for the final laminate layer with black pigment

- Application of an additional resin coat as a top coat with black colored resin

It is important to pay attention to UV-resistant and, above all, UV-shielding pigment. Relevant information can be obtained from manufacturers and distributors of GRP products.

Damage caused by design elements

Plastic ponds should also complement the garden naturally and harmoniously. A variety of design elements are conceivable for this, from plant pots to stones to decorative sculptures. As tough as the glass fiber reinforced plastic material is, it reacts sensitively to point loads from edges, corners or minimal contact surfaces and can sometimes even tear and develop holes. Therefore, when using such objects, it is worth using protective intermediate layers, for example made of:

- Rubber

- impact and tear-resistant film

- Natural materials, such as cork or raffia (limited shelf life!)

- Pavement slabs made of concrete or artificial stone

ATTENTION:

Many of these protective mats have their own buoyancy and have to be temporarily kept under water before they are weighed down by the elements to be supported. Large, round pebbles, such as those often used in eaves strips around buildings, are suitable for this.

Laminating pond instructions

Preparatory work

- Dig up the earth!

- Loose soil must be firmly secured!

- Introducing a thin bed of sand.

- Instead of plastering a sand bed, plastering mortar can be used, especially on steep surfaces.

Lay out the film and laminate it

- Line the surface with polyester film (0.2 mm)!

- No foil is necessary on plastered surfaces.

- The surface must be dry!

- Laminate the first glass mat - you take pieces of about 1 x 1 meter or a little smaller, place them on the film and soak them with resin!

- The resin as a hardener must be dosed very precisely! It's best to weigh it.

- It is best to use plastic buckets.

- Mix the materials well!

- Do not mix more than can be used in the next 20 minutes!

- Roll out all air pockets cleanly! The mats must be well soaked!

- This is how you deal with the whole pond piece by piece

- The tools must be washed in styrene from time to time

- Curing takes 3 to 5 hours. It's better to let everything dry overnight.

- Where bubbles have formed, sand the area, including where sand is sticking out on the resin or on the fibers!

- More layers are applied. Usually 2 to 3 coats are enough.

- The finish is a layer of glass mat 225 g/m², which is soaked with black colored resin. The final layer (225 g/m²) has a smoother surface than the normal 450 mats.

- Sand off uneven areas or sharp elevations!

- At the very end, the pond is painted with black colored resin.