- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

Concrete is not just concrete, so anyone who discovers the term lean concrete first asks themselves what it could be. Lean concrete has a very low cement content, which is why it gets its name. Therefore, it cannot be used everywhere where conventional concrete is needed. Everything about properties, processing and prices is explained in the following article.

Features

Lean concrete has a lower cement content than other types of concrete. This is also why it gets its name. The proportion of gravel, on the other hand, is very large, which has given this concrete the following properties:

- very low compressive strength

- is due to the small proportion of cement in the gravel

- low static load capacity

- water permeable

- also very sensitive to weather conditions

Tip:

Even if lean concrete is a lot cheaper than conventional concrete, it should not be used in places that require high load capacity or high compressive strength. Then savings are being made in the wrong place, as the lean concrete cannot withstand it for long.

Application options

Due to its low resilience, there are only limited places of use. For example, it is used to secure sealing systems as a secure layer around these systems. But lean concrete is also used on areas of land that have been damaged. Lean concrete can be used primarily in the following places:

- for leveling out unevenness

- as a protective or cleanliness layer

- for fillings or solidification

- for damaged slopes

- when a foundation leans to one side

- this is how a level level can be achieved

For example, a clean layer usually consists of gravel, which is placed approximately 5 centimeters high below the concrete that is actually to be poured as a foundation. Lean concrete can also be used here, which can ensure an even better hold of the future wall or house wall than just pure gravel.

Tip:

Lean concrete is a cement-gravel mixture in which one part cement contains eight parts gravel. It is usually used earth-moist. Due to the small proportion of concrete, the mixture was called lean concrete.

Use in horticulture

The lean concrete is particularly suitable for use in horticulture. Here it can be used for the garden bed border, especially because it is the cheapest variant of building materials. But lean concrete can also be used as the foundation for tool sheds, a light garden house or a carport. However, if a garage or garden house is being built, then lean concrete is not recommended for this. A slope can also be well secured with lean concrete. However, the slope should not be more than one meter high. Other ways to use lean concrete in the garden include the following:

- for filling foundations for a well

- Lean concrete does not wash out

- what could happen with a simple layer of gravel

- concreting fence posts (palisades)

If you only want to provide support to a structure that is subject to little load, then the inexpensive lean concrete can be used.

Processing

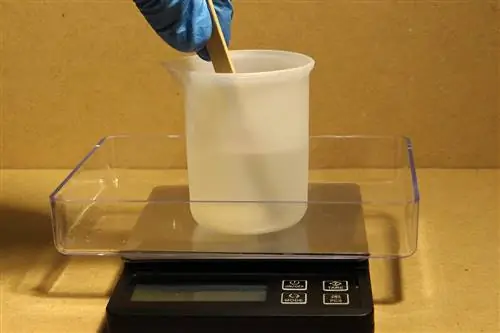

Due to its substance, lean concrete can either be purchased ready-made wholesale or easily mixed yourself. Especially when it comes to smaller quantities that are to be used, it makes more sense to mix the lean concrete yourself. A wheelbarrow, in which the concrete is enriched with water and mixed with a shovel, can be useful for this purpose. But a mixing machine, which can be rented from well-stocked hardware stores, is also recommended, especially because mixing by hand can be very strenuous. The lean concrete is mixed as follows:

- Cement, one part

- Gravel, eight pieces

- Water

The water is always mixed with a portion of cement until a slurry is formed. Four parts of gravel are then added to this. If the lean concrete is to be spread over a large area and it needs to be more liquid than, for example, to support a slope, then it should be mixed more firmly. Therefore, check the water content after the first mixture and continue adding the remaining cement and gravel.

Tip:

When used over large areas, the lean concrete can be very liquid, which makes it easier to distribute and straighten with the concrete scraper.

Finished lean concrete

The finished lean concrete is the so-called transported concrete, which is delivered with a concrete mixer and poured directly onto the desired area. However, such a purchase is only recommended for a certain quantity, otherwise it will be too expensive. Even if strength is guaranteed, this can be achieved just as easily with the right instructions for mixing yourself. Especially if very little lean concrete is needed, it makes more sense to use a bag of cement and simple gravel.

Prices

The prices for lean concrete vary because it depends on how much is needed. If only a small amount is used or for medium consumption, for example to attach several fence posts around the property, you can mix it yourself. To do this, a previously calculated amount of cement and gravel must be obtained and mixed. However, for a larger area, for example to build a carport, it is advisable to order ready-mixed, transported lean concrete. Unfortunately, ready-made lean concrete in a bag, to which only water is added, is not available commercially. The prices for mixing yourself and the finished lean concrete are as follows:

- Gravel is available from 10.00 euros for 1000 kg

- A bag of cement can be purchased from 3.00 euros per 25 kg

- a cubic meter of lean concrete transported costs between 89.00 and 101.00 euros

- Price depends on the compressive strength

- For cleanliness layers, for example, the price is between 99.00 and 101.00 euros

Due to the prices listed here, it makes sense to order the lean concrete to be transported when the required quantity is two to three cubic meters. Anything less than this should be mixed yourself for cost reasons. Of course, the working time must also be taken into account, which requires many hours when mixing yourself.

Tip:

If the concrete is mixed yourself, any costs for materials that are not yet available must also be taken into account. For example, renting a mixing machine. If lean concrete is transported, there are usually additional travel costs that need to be clarified beforehand.