- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

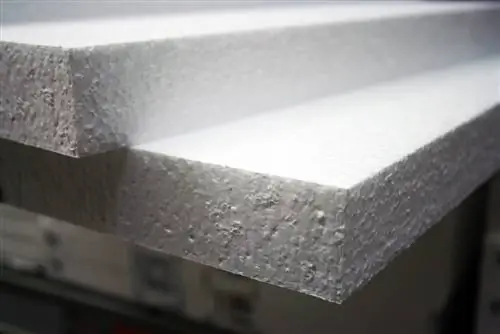

Attaching veneer to boxes or wooden panels can be done by ironing and gluing and can beautify and visually change both furniture and other objects in a short time. However, to ensure that wrinkles do not form or the veneer does not break, a few basics must be observed. We'll reveal what these are in the following step-by-step instructions.

Utensils

Ironing veneer is comparatively easy and makes it possible, for example, to upgrade old furniture or beautify speakers. The worktop in the kitchen can also be given a clean and decorative finish by ironing it on. However, various utensils are required for this. These are:

- pencil

- Iron

- cutter knife

- Ruler

- Foam roller and brush

- Sandpaper or sander

- Cut-resistant underlay

- self-adhesive veneer or veneer panels and wood glue

- Spatula or squeegee

- cloth

- Water spray bottle or damp cloth

- Angle

Preparation

So that ironing and gluing can be done in one step, the appropriate preparations must be made. The following steps are important:

Bows

The surface to be glued is smoothed and roughened with sandpaper to enable optimal adhesion of the glue. For larger areas, we recommend using a sander, as it produces the desired result more quickly and saves effort.

Measuring & Marking

To stick on a surface, the veneer sheet should be one centimeter longer and wider than the dimensions of the board. In this way, a clean finish can be created at the edges. First, use a ruler or protractor to measure the surface that is to be covered. The dimensions are transferred to the veneer sheet. The craftsman's tip to measure twice and cut once - should definitely be taken into account, because self-adhesive veneer pieces or those prepared with hot-melt adhesive are comparatively expensive to purchase.

Crop

After measuring and recording the dimensions, the veneer can be cut to size with a cutter knife on a cut-resistant surface. It is advisable to first scratch the lines on the back of the veneer with the tip of the cutter knife. The blade is then cut along a ruler or angle. Caution is advised, as on the one hand the knife is very sharp and on the other hand the veneer sheet can break comparatively quickly.

Moistening

For processing and ironing, it is advisable to moisten the material in advance. To do this, wipe the outside of the veneer with a damp cloth or moisten it with a spray bottle.

Leimen

If the choice fell on pieces of veneer that do not already have hot melt glue, both the wooden surface and the back of the veneer must be coated with wood glue. This step is also part of the preparation because the wood glue has to dry. Depending on the glue and material, this takes ten to 40 minutes. To ensure that the glue has reached the correct consistency, it should be gently tapped with your finger or fingernail. If the surface feels like adhesive tape or just slightly moister, the correct condition has been achieved.

Tip:

So that the glue does not dry too much, it should be checked every five minutes to see whether the consistency is correct.

Glue & Iron

When both the surface and the veneer are prepared, gluing and ironing can be done. The following instructions show which steps need to be taken into account:

- The imitation wood, which has been coated with glue and moistened on the outside, is aligned on the wooden surface so that there is an overhang of exactly one centimeter on all edges. In addition, attention should be paid to the course of the grain in order to achieve an even result.

- Using a spatula or a squeegee, the veneer wood is first glued to the surface from the inside out - i.e. from the middle to the outer edges - with light pressure. Air bubbles and wrinkles are removed and smoothed out. It may be necessary to moisten the outside again before smoothing and ironing.

- The iron is set to a low temperature, for example on the wool or delicates setting.

- Just like with the squeegee, use the iron to paint from the inside out with light pressure. The edges should be ironed over so that the veneer board adheres well to these areas.

- When the veneer panels have cooled down and adhere well to the surface, the ruler or square is applied again. Square or ruler are brought edge to edge with the wood. The protruding veneer ends are then scored with a cutter knife and broken off or cut off using the ruler. Since this is a difficult job, it is advisable to test it on a sample beforehand. In addition, any protruding veneer residue on the edges should be sanded off with the sandpaper. This reduces the risk of pieces breaking off.

Cutting

When processing veneer sheets, residues are often left over. This is often the case, especially with smaller workpieces. Since self-adhesive veneer in particular is comparatively expensive to purchase, it may well be worth using these leftovers. However, the correct procedure should be followed. Here too, the corresponding steps must be taken into account:

- Place two pieces of veneer on top of each other at the edges so that at least one centimeter of one part is above one centimeter of the other part. However, an overhang of two to four centimeters is better. The pieces should be placed on a cut-resistant surface.

- To align the two pieces, a ruler, level or square should be used to get a straight and clean line. It also makes sense to fix the pieces to prevent them from shifting and to make cutting easier.

- Use a ruler and the tip of a cutter knife to pre-score a line on the top veneer sheet.

- In the prepared line, the veneer sheets are cut through with the cutter knife and greater pressure. Because both panels are cut through at the same time, there is a perfectly matching line on both pieces, allowing them to be joined together almost seamlessly. The procedure is also ideal, for example, when slanted lines or corners need to be cut.

Note:

With this procedure, too, attention must be paid to the course of the grain. Otherwise, the interfaces will fit together, but the differences in the grain can be unpleasantly noticeable.

Sealing

After applying the veneer, it makes sense to seal the surfaces. This protects them from external influences and increases their service life. Cleaning is also made easier. We recommend the following for sealing:

- Hard wax oil

- Wood protection glaze

- Clearcoat

Before applying, the surface should be sanded again with sandpaper. This roughens the veneer board and makes it more receptive to sealing. The hold is increased, improved and extended. Experience has shown that using a plastic roller makes the most sense for an even application.