- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

Having your own swimming pool in the garden is a real luxury. So that this oasis can be used even when the outside temperature is cooler, a pool heater is necessary. Wood appears to be an attractive method to heat water effectively. The raw material is renewable and burning it creates a campfire romance. Building such a variant is not difficult and does not require high expenses.

Inspiration from Scandinavia

Wooden hot tubs are common in Sweden. Heating with pine, spruce or birch is normal not only in the house but also in the sauna and pool. To make more efficient use of fire heat, the Swedes build stainless steel ovens directly into the pool. These models are fired through an opening in the upper area. Exhaust gases enter the air via a chimney. The advantages of this variant are versatile:

- Stainless steel conducts heat directly to the water

- no energy loss via hose lines

- Firing from the pool possible

Building your own stainless steel furnace requires not only welding skills, but also expensive materials. But this Scandinavian variant offers inspiration for alternative solutions. With recycled materials and a little craftsmanship, you can build a wood-fired pool heater that sits outside the pool.

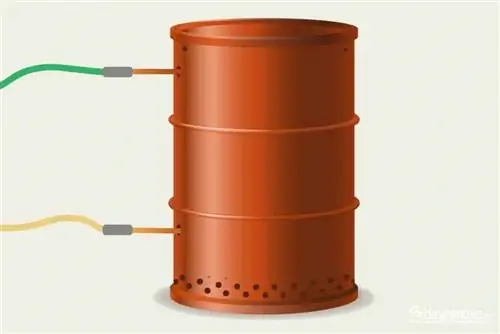

Build an external fire barrel

In this variant, the pool water is led through copper pipes that run through a fire barrel. The fire heats the water, which then flows back into the pool. This variant is suitable for pools with a volume of around 30,000 liters. For larger pools, the efficiency is not sufficient to bring the water temperature to a comfortable level. To build the water heater you need:

- an old oil drum: 60 liter capacity

- thin-walled copper pipe: 10m length, 15 mm diameter

- Hittsaw and metal drill

- used grill grate, perforated sheet metal or sturdy wire plate

- Hammer and nails

- Clamp connectors and hose connections

Costs

The copper pipe represents the largest cost factor in this construction project. Depending on the provider, you can expect to pay four to six euros per meter for a 15 millimeter thick pipe. If you don't have an oil drum available, look for discarded models at used markets. A new metal barrel of this size costs around 30 to 40 euros. Nails and fasteners cost around ten to 15 euros.

Tip:

For a smaller model, you can convert an old beer barrel into a combustion chamber. This gives the barrel a new use.

Construction instructions

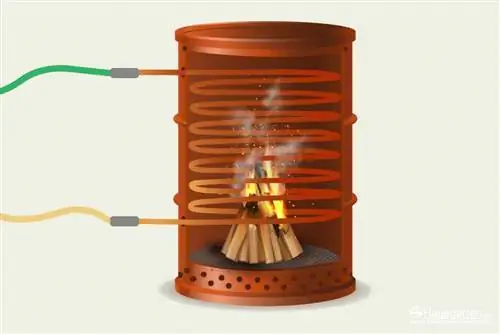

Saw the cover completely off and drill holes in the bottom area in two staggered rows. These openings are used to supply air so that the fire can later burn well inside. Further openings in the upper area ensure that smoke and gases can be evacuated. The openings should have a diameter of two to three centimeters. The smaller the holes, the more openings the fire barrel needs. Since the wood should ideally burn above the ventilation openings, a precisely fitting and coarse-meshed storage area for the wood is integrated in the middle area. Drive long nails into the barrel from the outside so that the ends point into the interior. They serve as a fixation for the wooden shelf. Slide the cut piece into the barrel from the top before placing the spiral bent copper pipe.

Tip:

Fill the copper pipe with sand and pour water into it. You can then bend the tube into shape over a resistance such as a wheel rim.

Form run

The copper pipe runs along the walls of the fire barrel, with the water flowing through the pipe from bottom to top. To increase the efficiency of the self-made instantaneous water heater, you should also bend the upper part of the copper spiral along the barrel opening into a spiral. The flames burn below this spiral and the rising heat is used optimally. The inflow and outflow are guided through additional openings in the combustion chamber so that the system can be connected to the filter system outside the barrel:

- Inlet and outlet provided with crimp connector

- Place the hose adapter on the crimp connector

- Connect the inlet to the return line of the filter pump

- Direct drain into the pool

Application and mode of action

Light a fire on the shelf in the combustion chamber and place the lid on the barrel. The chimney effect ensures optimal air supply because the fire draws air through the openings into the interior. The metal wall of the combustion chamber concentrates the radiant heat of the fire. The smallest amounts of wood can be used efficiently. They burn completely, producing high temperatures. A fan ensures better burning effects. In this case, you should ensure optimal water flow so that the heated water quickly enters the pool. A circulation pump supports the flow. With an air temperature of around 18 degrees Celsius, it can take up to eight hours for the pool to heat up to 28 to 30 degrees Celsius.

Alternative: solar heating

A wood-fired pool heater must be operated for a long period of time to achieve the desired effect. A more convenient option is to use alternative energy sources such as solar energy. A simple variant is to lay a 50 meter long garden hose on the roof of the gazebo in a spiral arrangement. The system is connected to the return from the pool filter. It requires a powerful pump for the water to flow through the hose.