- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

The types of concrete are as versatile as its use as a modern building material. Divided into classes, there is the right concrete for every use. We explain which species and classes there are.

Types of concrete

Where in its early days over two thousand years ago concrete was “just” a homogeneous replacement for stone that was easy to produce on site, today the building material impresses with its enormous specialization for a wide variety of uses. Depending on the requirements, the composition and properties can vary greatly.

Insulating concrete

Classically, concrete generates its enormous load capacities via a high density of around 2.0 to 2.5 kg / dm3. This is accompanied by extremely poor insulating properties. In order to make the need for additional insulation materials obsolete, insulating concrete also has acceptable insulation values.

- Task: Production of load-bearing components with an insulating effect

- Special feature: Additives such as natural pumice, expanded clay or foam glass as air entraining agents

- Application examples: Components or buildings with a concrete look with thermal insulation requirements

Fiber concrete

As an alternative to the well-known reinforcing steel, various fibers are introduced into fiber concrete to increase the load capacity.

- Task: High load capacity with small component dimensions

- Special feature: Glass fibers, textile fibers or rarely metal fibers as a replacement for reinforcing steel

- Application examples: slim components, such as facing shells, furniture or garden objects, etc.

NOTE:

Normally, depending on the intended use, concrete must have a certain concrete cover over installed steel as corrosion protection. With non-metallic fibers, the coverage can be significantly lower and the component dimensions can therefore be significantly reduced.

Easy to work concrete (LVB)

LVB is designed to be processed as uniformly as possible and without damage in terms of the grain size and additives used. It meets high technical and visual requirements with easy installation

- Task: Simple installation in narrow, complicated formwork with dense reinforcement without defects, gravel pockets, etc.

- Special feature: Maximum grain size usually 8 to 16 millimeters, often addition of superplasticizers and setting retarders

- Application examples: Exposed concrete components, slim columns or beams

Translucent concrete

Although there is no real “transparent” concrete. However, it is possible to make it translucent for special effects.

- Task: Transport of light through the concrete component as an effect or for basic brightness

- Special feature: Fiberglass mats or bundles embedded in layers as light channels

- Examples of use: Art installations, public buildings, museum and sacred buildings

ATTENTION:

Incorporating glass fibers into the concrete limits the use of reinforcing steel. The more light transmission is desired, the more the load-bearing capacity of the component is limited.

Normal concrete

The most commonly used type of concrete is normal concrete. We always speak of normal concrete when the basic mix is not modified into a special type of concrete by additions, installations, etc.

- Task: Production of normally resilient concrete components without special requirements

- Special feature: Mass usually between 2.0 and 2.5 kg/dm3, compressive strength 5.0 to 55.0 N//mm2, curing up to standard strength according to DIN occurs after 28 days

- Application examples: Walls, ceilings, foundations etc.

Recycled concrete

Recycled concrete takes up the trend towards more sustainability and, depending on the desired properties, replaces parts of the mineral aggregates with recycled building rubble. Aggregate properties such as grain size, grading curve, load capacity, etc. are retained unchanged and taken into account.

- Task: Reducing the consumption of finite resources

- Special feature: processed building rubble as a substitute for mineral aggregates (sand, gravel, grit)

- Application examples: depending on the concrete class such as types of concrete without recycled building materials

Spincrete

Spincrete describes the production of axially symmetrical linear components, such as posts, masts, tubes, etc. in rotating hollow forms.

- Task: Highly compressed, thin-walled components with high load capacity through the use of centrifugal force

- Special feature: Strongly layered structure due to ingredients of different weights in the centrifuge

- Application examples: Electricity pylons, concrete pipes etc.

Self-compacting concrete (SCC)

Inadequate compaction often leads to visual and technical defects in the concrete component due to difficult access to the formwork or extremely dense reinforcement. Self-compacting concrete, on the other hand, does not require mechanical compaction through shaking or tamping.

- Task: Avoidance of defects, gravel nests, etc. in narrow formwork

- Special feature: High uniformity without mechanical compaction methods due to the strong addition of plasticizers and setting retarders

- Application examples: Exposed concrete components, delicate components such as columns and beams, bridges etc.

Exposed concrete

For some time now, many designers have consciously used concrete as a visible surface. For a high-quality look, it is important to have a surface without air bubbles or gravel pockets.

- Task: high-quality optical surface

- Special feature: Heavy use of plasticizers, sometimes colored additives to change the appearance

- Application examples: Buildings with exposed concrete look, engineering structures such as bridges, retaining walls, underpasses etc.

Prestressed concrete

The load-bearing capacity of normal reinforced concrete can be further increased if the entire component is placed under tension from the outset in the opposite direction to the subsequent load direction. We then speak of so-called prestressed concrete or prestressed concrete

- Task: Increasing resilience

- Special feature: Installation of tension wires, tension cables or tension rods, which are technically tensioned after the concrete has hardened (mainly by screwing)

- Application examples: Industrial structures, traffic structures (bridges!)

Stamped concrete

Without reinforcement and only compacted by mechanical impact, stamped concrete is the oldest type of concrete ever. It is particularly common in existing buildings, for example on foundations or massive bridge pillars.

- Task: Absorbing pressure loads, often in foundation components

- Special feature: no reinforcement, installation in layers and compaction by tamping

- Application examples: Formerly for all concrete components, today still occasionally in horticulture as foundations and for other subordinate components

Concrete classes

Today, there are a whole range of different classifications in order to obtain exactly the concrete desired or required for a task. Each classification considers a different property. As a result, technical names for a particular concrete can now include a whole range of different definitions. The typical classification is:

Compressive strength class

The decisive factor for the resilience of a concrete is the pressure that it can withstand when it has set. Typical designations are a “C” for “Concrete” and two numbers separated by a slash. The first (smaller) indicates the load in N/mm2 for a cylindrical test specimen, the second number for a cube-shaped test specimen. Common compressive strength classes are:

- C8/10 (e.g. for lean concrete for minor soil improvements, in horticulture, etc.)

- C12/15

- C16/20

- C20/25

- C25/30 (common for many types of normal concrete, e.g. in classic house construction)

- C30/37 (from this class onwards it can usually only be produced with special technical equipment)

- C35/45

- C40/50

- C50/60

-

C55/67

etc.

- C90/105 (from here on there is no longer any general approval, therefore approval is required in each individual case, production is technically only possible as spun concrete)

- C100/115

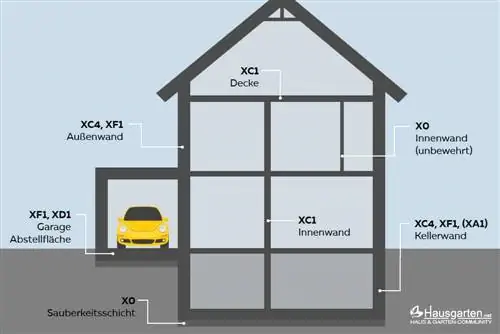

Exposure class

Depending on how strongly a concrete component is exposed to environmental influences, it must be able to offer long-term resistance to these influences. For this purpose, concrete is divided into different exposure classes:

- X0: Unreinforced concrete and foundations without frost, no risk of attack for concrete and / or reinforcement

- XC (1-4): Interior or foundation components with high humidity (swimming pool, stables, laundries, etc.), open structures

- XD (1-4): Components in the spray mist area of traffic areas, roadways, brine pools

- XS (1-3): Exterior components near the coast, as well as harbor facilities, quay walls, etc.

- XF (1-4): Traffic areas treated with de-icing agents, seawater components, scraper tracks

- XA (1-3): Components exposed to chemical attack, such as wastewater treatment plant tanks, liquid manure tanks, fermentation feed silos

- XM (1-3): Wear stress, e.g.: on industrial floors

In addition, four quality classes W0, FW, FA and WS describe the concrete quality for components exposed to moisture.

Consistency class

Depending on the intended use, concrete with certain flow or stability properties may be necessary:

- C0: Very stiff, not DIN EN206

- F1: stiff

- F2: plastic

- F3: soft

- F4: very soft

- F5: flowable

- F6: very flowable

- F6: SCC (self-compressing)

Aggregate

Depending on the requirements, different aggregate sizes can be used for the concrete. A distinction is made between sand concrete, gravel concrete or chipped concrete. The grain size used is indicated by the maximum diameter (Dmax).

Graphic density

Depending on the density of the concrete, it is divided into three categories.

- Lightweight concrete

- Normal concrete

- Heavy Concrete

Each of these categories is further divided into raw density classes by DDIN EN206, from which the raw density is determined. For lightweight concrete, for example, there are 6 bulk density classes D1, 0 to D2, 0, where D2, 0 means a bulk density between 1,800 and 2,000 kilograms per cubic meter of concrete. The bulk density of a concrete is important for the dead weight of a component, but also for the definition of a load by a concrete component.

Typical names

A particular concrete mixture does not always have to be classified in all available classes. Sometimes it is sufficient to determine, for example, the load and the exposure class, while density and grain size are irrelevant for the intended use. A typical concrete for foundation components, such as foundations, floor slabs, etc. is approximately:

C25/30 XC1

This is a typical normal concrete of medium load capacity with a low resistance to moisture, as can be used in normal components in contact with the ground without pressing groundwater, etc.