- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

Having breakfast comfortably on the balcony - that doesn't have to be a dream, even if your home doesn't yet have a balcony. With an extension balcony kit, the balcony can be added very easily at a later date compared to other systems. However, a few points must be taken into account when selecting and setting up.

Balcony types

There are essentially three types of balcony:

- self-supporting balconies, like the projection balcony

- partially self-supporting balconies

- Cantilever balconies without supports

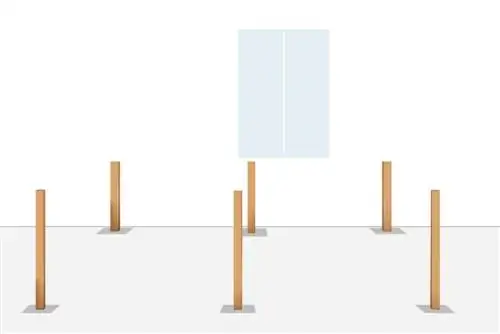

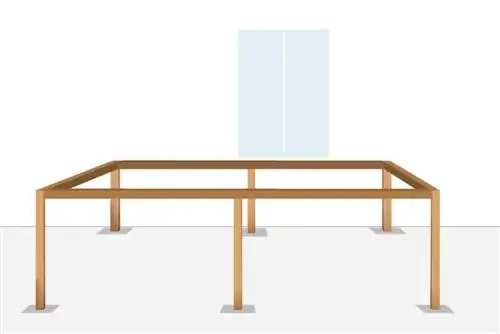

Self-supporting balconies stand on four supports and are only attached to the house facade to prevent them from falling over. Therefore they are also known as front or front balconies. In terms of the necessary structural changes, they require the least effort and incur the lowest costs.

Partially self-supporting balconies rest on two supports and therefore require a more resilient fixation to the house wall. Fastening to the facade requires more effort and is also more expensive because it always has to be carried out professionally. Cantilever balconies do not require any supports, meaning they are completely fixed to the house wall. The effort required for planning and construction is correspondingly high and cost-intensive. This makes them the most expensive type of balcony.

Showroom balcony

The front or front balcony is the easiest way to retrofit a balcony. The balcony floor rests on four supports, is leaned against the house wall and fastened here. So it is already stable in itself and is only secured against falling over under uneven loads or extreme weather conditions.

The greatest effort in its construction comes from the necessary wall breakthrough for access to the balcony. Due to the simple construction, it is also possible for laypeople to assemble at least part of a corresponding balcony kit on their own. This in turn can save costs.

Material

Balconies are usually made of concrete, steel, aluminum or wood. The materials differ not only in terms of appearance, but also in terms of acquisition and follow-up costs as well as their properties:

Concrete

Concrete is heavy and therefore more difficult to assemble. The material costs are low, but the assembly costs are higher than with lighter materials. Concrete is also easy to maintain, so it requires little effort and ongoing costs.

Steel

Steel and stainless steel are still relatively heavy, but lighter than concrete. The materials are more expensive to purchase than concrete, especially stainless steel. Depending on the size, assembly is similarly complex. Follow-up costs arise if the metal has to be sanded and protected against rust.

Aluminium

Aluminum is particularly light and is therefore easy to assemble. Due to its low weight, no crane or similar construction equipment is usually required for erection. The follow-up costs are also low. However, the material is significantly more expensive to purchase than concrete or steel.

Wood

Depending on the type of wood, the weight and cost of the wood can vary greatly. Spruce wood, for example, is particularly cheap. On the other hand, precious woods, such as eucalyptus, are very expensive. Installation is usually very simple, but additional costs for sanding and sealing must be taken into account.

Building permit and proof of stability

Before a projection balcony can be installed, a building permit must first be obtained. For this, proof of stability is also required. If you want to make it as easy as possible for yourself, choose a provider who delivers the systems directly with the kit. Otherwise, the responsible building authority is the appropriate contact person.

The costs for the building permit depend on the respective municipality, but on average are between 400 and 600 euros. To purchase the proof of stability, you will have to pay another 1,000 euros.

Material and kit costs

The costs for a wooden balcony kit depend on various factors. Below:

Type of wood

Cheap spruce or expensive eucalyptus wood - prices can range between around 600 and 2,000 euros per cubic meter. If you choose a cheaper type of wood, you can save considerable costs.

Size

One and a half meters deep and four meters wide or four by four meters - the size of the base area has an impact on material consumption and weight and thus on the necessary assembly effort. The larger a balcony is, the more expensive it becomes in several respects.

Scope of the kit

Simple kits for imaginary balconies consist only of the supports, the balcony floor and the necessary assembly material. The railing is not included in the price for such a kit. When making your selection, you should therefore take into account not only the price for the floor space, but also the scope of the kit.

Additional costs

A kit for a small wooden balcony is available in an inexpensive version starting at around 3,000 euros. But that's not all the costs associated with the purchase and installation.

In addition:

- Delivery costs

- railing and handrail

- Wall breakthrough for access to the balcony

- Door and installation of the balcony door

- Montage

- Subsequent costs for care, protection and sealing of the material

Example calculation for the pre-set balcony kit and assembly

For the cost example, a simple imaginary balcony kit made of glued wood without railings is chosen. The footprint of the balcony should be 1.5 x 4 meters. The costs are therefore made up of the following elements:

- Balcony kit: 3,000 euros

- Wooden railing, 7 meters long: 90 euros per meter / 630 euros total

- Assembly costs and installation of the door: 4,500 euros

- Balcony door: 800 euros

- Building permit: 500 euros

- Proof of stability: 1,000 euros

The costs for this simple, small balcony are therefore 10,430 euros or 1738.33 euros per square meter of balcony. Even small changes in the material of the balcony or railing can increase the price significantly. Even 2,200 euros per square meter of balcony space is still considered extremely cheap.

Balcony kit - savings options

Some ways to save costs have already been mentioned. If you want to keep the price as low as possible, you can use the following points as a guide:

Door

Simple revolving doors with a plastic frame cost between 250 and 300 euros. They are therefore significantly cheaper than tilt and turn doors or variants with higher quality frames.

Thermal protection

The higher quality the glazing on the door, the more expensive it will be. On the other hand, a thermal protection door continuously saves heating costs.

Wall breakthrough and installation of the door

If the door is used in an already partially existing wall opening - for example instead of a window - the costs can be reduced.

Proportionately carry out assembly yourself

With a lot of experience and appropriate knowledge, it is entirely possible to take on part of the assembly of the kit yourself. However, some tasks, such as breaking through the wall, should and must be carried out by a specialist.

Tip:

Comparing the cost estimates from different providers gives you an idea of what prices you can expect for your own ideas. On the other hand, it makes it easier to compare different elements with each other and find the cheapest prices.