- Author admin [email protected].

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

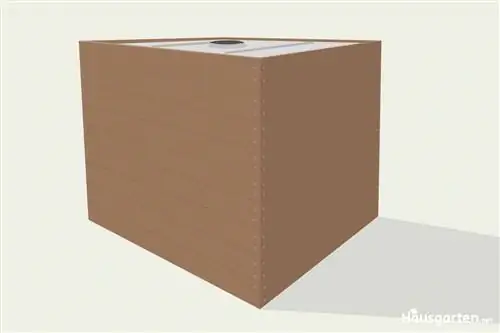

IBC containers are ideal for collecting useful water in the garden. So that the plastic containers fit better into the overall appearance of the green area, appropriate cladding made of wood, stone or special foil ensures that the IBC container is much more attractive.

Material selection and preparation

First, choose a location with solid ground so that the IBC container cannot slip and stands upright. It is possible to cover the container with stones, but it ties it to a permanent place in the garden. Special films to cover the container maintain its mobility and are quick to assemble. The films are available in all imaginable colors and thicknesses. The stronger the material, the more durable the film. High-quality films impress with their UV resistance and excellently crafted seams and zippers. Some manufacturers even offer thermal foil that ensures that the contents of the container do not freeze as quickly on cold nights.

Tip:

Waste wood or discarded Euro pallets are also often used to build cladding for IBC containers. These variants are particularly resource-saving and sustainable. Euro pallets in particular are very robust and durable. Nevertheless, it makes sense to treat it with appropriate wood protection varnishes or oils to make it even more durable.

Wood as natural and sustainable cladding for the IBC container

The most beautiful and natural thing is a self-made wooden paneling. Wood is a renewable raw material and fits perfectly into the overall look of the garden. Tongue-and-groove boards that can be easily put together are best. Oak and larch are naturally extremely weather-resistant and ensure stability and an optical enhancement of the water storage tank.

Acrylic varnishes or special glazes as well as linseed oil varnish are suitable to protect the wood. The latter is a 100% organic and therefore natural wood preservative that has been used for centuries to preserve door and window frames and timber frames.

The tools and supplies required to build the cladding are manageable:

- Cordless screwdriver,

- galvanized SPAX screws,

- Hand circular saw,

- Folding Ruler,

- a 90 degree angle

- Wood protection paint

- and brush or paint roller

are enough to realize the project.

Be sure to note

If the destination of the IBC container does not allow the structure to be built around the container, several people will be required to lift the cladding over the container. Depending on your preference, it is possible to create a lid for the IBC container cladding with a little effort.

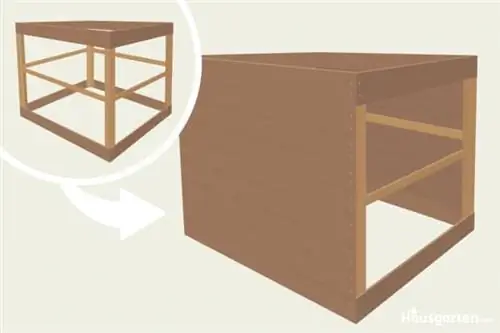

Note: Depending on the thickness of the wood, additional struts may make sense. Constructions that have a complete frame made of wooden slats are particularly stable. These must then first be screwed together like the edges of a box. This scaffolding can then be placed over the IBC container and conveniently covered with the wooden boards.

Step-by-step instructions

120 x 100 x 116 cm are the dimensions of an IBC container. A typical dimension for tongue and groove boards is 2.2 x 12.1 x 240 [cm]. In this example, ten boards would be necessary to cover both long sides (116 / 12, 1=9, 5). Another ten boards are required to plank the cross sides. There are also wooden slats for the framework. If all materials and tools are available, proceed as follows:

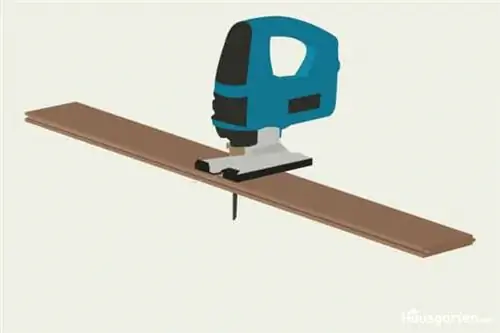

- Material cutting: Saw ten of the boards in half (120 cm) and break the edges with sandpaper. Cut the ten remaining boards to at least 100 cm + 2 x the thickness of the boards + 2 x the thickness of the wooden slats used and also break the edges. Cut eight wooden slats to 121 cm (10 boards x 12.1 cm=121 cm).

- Treat wooden elements with protective varnish or glaze and allow to dry.

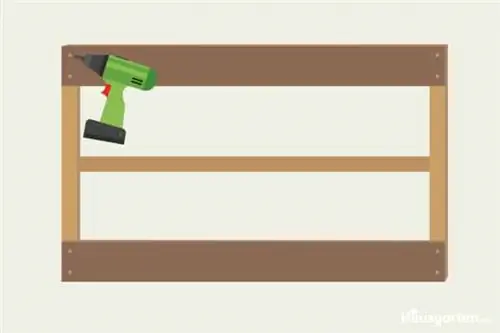

- Screw two of the wooden slats flush with the corresponding wooden boards at a distance of 120 cm. Another wooden slat in the middle provides additional stability.

- Set up the side panels and screw them flush with the remaining tongue and groove boards. Another wooden slat in the middle provides even more stability. The 90 degree angle helps align the side walls correctly.

- Now lift the panel over the IBC container and, if desired, attach it to the pallet.

Frequently asked questions

What should you pay attention to when building the wooden cladding for the IBC container?

When selecting materials, it is important to pay attention to strength and weather resistance. Material that is too thin looks cheap and is quickly unstable. Inferior varnishes do not protect the wood adequately, so the construction begins to rot and fall apart after a short time.

Can I also bury my IBC container?

IBC containers are not cisterns and are not designed to be used as such. Damage and leaks after burial cannot be ruled out. Cladding using suitable materials such as wood or special foil also simplifies maintenance.

Which surface is suitable for an IBC container?

IBC containers should stand upright and not slip even when emptied. If a pallet truck is available, it is recommended to set it up on a solid surface. This means the container can be moved at any time and remains mobile.

How much wood do I need to cover an IBC container?

The dimensions of an IBC container are 120 x 100 x 116 cm (LxWxH). This results in an area of 2 x 1.20 x 1.16 + 2 x 1.00 x 1.16=5.104 m². Since the cladding has to be a little larger than the IBC container and a waste of five to ten percent is to be expected, around six square meters of wood are necessary to clad an IBC container.