- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

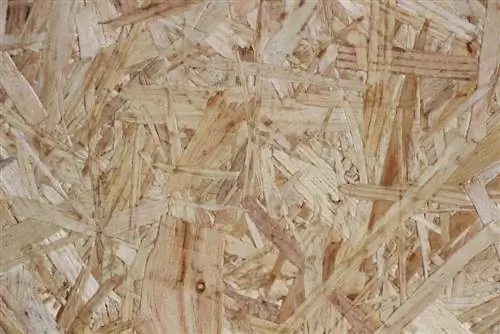

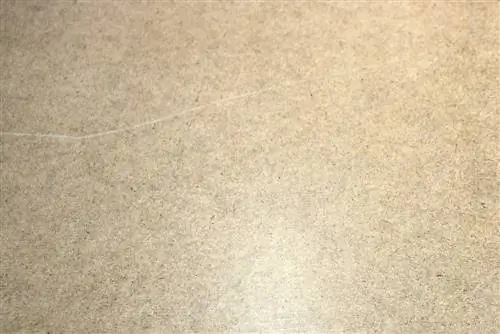

MDF boards are available in various sizes and thicknesses and can be used in a variety of ways. However, evaporation and possibly mold must also be expected from the panels, which is why they are not fully suitable for every interior. With the right selection and coordinated means, the appropriate adjustments can be made even here.

MDF boards - properties

The MDF boards or medium-density fiberboard or medium-density wood fiberboard are, so to speak, made from waste. Thin logs and leftovers from industry go into production, are pressed and glued. Due to their production and material, MDF boards are comparatively easy to work with, robust and versatile.

Depending on the impregnation and processing, the MDF panels can be used outdoors or indoors. The plates therefore have many advantages. However, not all of the properties are positive, as becomes clear from the list:

fragility

The plates are comparatively brittle at the edges. This must be taken into account during processing, as sections can quickly break off when sawing and drilling.

Exhalations

In the past, MDF boards were mainly processed with formaldehyde, which led to harmful fumes. Therefore, the panels were reluctant to be used indoors. The recent processing with resin-containing glues reduces the he alth risk, but does not completely eliminate it.

Editing

The panels are very easy and simple to cut and drilling is also very easy. However, it is essential to pre-drill for screwing, as the material can quickly tear when screws are inserted from the side and, as mentioned, the edges can break away.

Insulation

The panels have an insulating effect against heat and vibrations. They can also be used as a comparatively inexpensive insulation material.

Mold

The plates are susceptible to mold. Use in damp areas or outside is therefore only advisable after special treatment.

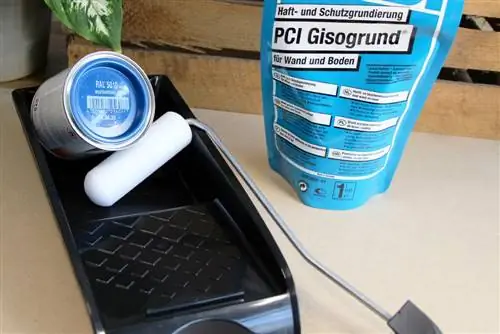

Paints and paints

MDF boards can easily be treated with varnishes, paints and waxes to give the surface the desired design and at the same time insulate it and make it more resistant.

Price

For one square meter you can expect costs between three and eleven euros. The costs depend primarily on the thickness of the MDF board. However, there can also be the cutting, which is often not exactly cheap.

Thicknesses and dimensions

The MDF boards are available in many different thicknesses. This is also a clear advantage. Boards with thicknesses ranging from two to 60 millimeters thick are commercially available. However, the following thicknesses are particularly common:

- 6mm

- 8mm

- 10mm

- 12mm

- 16mm

- 19mm

- 22mm

- 25mm

- 28mm

- 30mm

- 38mm

Common dimensions are 280 x 207 centimeters and 411 x 207 centimeters.

Indoor and wet areas

An MDF board with the B1 marking has a fire-retardant effect, which is why it is ideal for interior work. However, possible fumes should not be forgotten. If the panels are to be used indoors, care must be taken to use safe glues and binders. If the MDF boards are to be used in a damp area, special treatment must be carried out. As mentioned, the material is susceptible to mold. If the panels are still to be used in damp areas, they must have a suitable impregnation.

Outdoor area

Outdoors, MDF boards have to withstand many influences. Heat, cold, humidity and frost pose challenges. In order for the material to be adapted to these challenges, it must be treated accordingly. Impregnation against moisture and temperature fluctuations is important. If moisture can no longer penetrate the material, the influence of high or low temperatures will also be reduced.

The possible evaporation of the material plays a smaller role when used outdoors, but it can still make sense to use MDF boards without substances containing formaldehyde. On the one hand, this will generally increase demand. On the other hand, the load is also reduced during processing and handling the material becomes safer.

Costs

The costs for an MDF board are very low in comparison. However, the prices should not be underestimated. The stronger the plate, the higher the cost. In addition, professional cutting may involve high costs. It is worth comparing prices in different hardware stores and also comparing providers online. In hardware stores, both the cutting and the prices for the MDF board are often cheaper (or even free) than, for example, from a supplier of building materials.

In addition, the prices depend on further preparation. Panels that have been treated with vapor-free agents are often somewhat more expensive. However, they are also less harmful to he alth and can therefore be used indoors without having to fear any he alth consequences.

Furthermore, other utensils as well as varnishes and paints must be taken into account when calculating the material costs or total costs. However, savings are made, among other things, on gluing.