- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

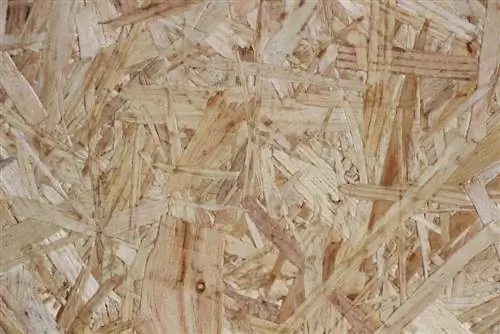

Do you need new wooden panels for your floor so that your living space looks fresh and attractive again? Then it's best to use OSB boards. Previously a waste product of the plywood and veneer industry, the“oriented strand boards” have been able to establish themselves on the market and are now often used for planking walls and ceilings, making furniture or for events. The secret of the properties lies in the chips, which are very long compared to other plates and are arranged in a crisscross manner before they are put into the press under high pressure and high temperatures. This gives them their typical surface and longevity.

Properties of OSB boards

OSB boards are so popular because they have numerous properties that are perfect for the professional sector, the hobbyist and even artists who want to express their ideas through the nature of the wood. The clever mind behind the coarse chipboard was Armin Elmendorf, who first presented the concept in 1963. Since then, the plates have been continually improved and now impress with the following properties:

- high bending strength due to chip shape

- high vapor barrier value thanks to the adhesive used

- suitable for invisible and artistic uses

- Form stability even under great force

- long lifespan

- extremely robust and impact-resistant

With these properties you can tackle a wide variety of projects without having to rely on classic plywood. In order to choose the right panels, you have to compare the individual panel qualities, which differ from each other in terms of properties and possible uses.

OSB board types

The plate types are defined by different aspects and properties that are essential for use. The most important points when comparing the plates include the following values:

Wood moisture

Wood moisture refers to the proportion of water in the material. Each type of panel is offered with a different wood moisture content and can therefore be used for different purposes, such as wet rooms or pavilions in the garden. Since the panels are naturally durable and moisture-repellent, they don't differ that much from each other, but the processing of the individual classes is perfectly tailored to different projects.

Usage class

The usage class is the official name of the plate type. These not only make it easier to select the individual panels when ordering or in the hardware store, but you also know exactly which projects you can use the individual panels for. A total of four usage classes are available, which are labeled OSB and the respective number and are explained in detail below.

Formaldehyde class

The formaldehyde class indicates how high the emissions from the individual plate are. Two classes are distinguished here:

- Class E1: 100 grams of material contains around 8 milligrams of formaldehyde

- Class E2: 100 grams of material contains between 8 and 30 milligrams of formaldehyde

However, you don't need to worry about the formaldehyde class, as OSB boards of class E2 are not approved in Germany. This means that the maximum formaldehyde content of the panels is limited to around 8 mg, which significantly reduces the pollution in your interior spaces.

Usage classes

All boards offered in Germany and Europe are standardized, which makes OSB boards a regulated product that must be manufactured according to certain guidelines. The essential standards include DIN EN 13986 and DIN EN 300, which determine how wood materials in construction must be constructed. This means that the individual types can be used without any problems without causing problems during or after installation. OSB boards are available in the following usage classes:

OSB/1

This OSB board is a variant that is mainly used for interior design, for example for making furniture or as a basis for floors. They can only be used in dry areas and the wood moisture corresponds to a temperature of 20°C and the ambient humidity of a maximum of 65 percent. These values may only be exceeded for a few weeks a year in order to guarantee the quality of the plate. Their easy processing makes them particularly popular in the USA. OSB/1 is rarely offered in Germany and is therefore unlikely to be profitable for you in most cases.

OSB/2

OSB/2 is a board type that has no longer been available in stores since 2014 and is an improved variant of OSB/1. It is used for load-bearing building purposes, for example structures that are open but covered outdoors, such as a pavilion or car canopies. The moisture content of the wood corresponds almost exactly to the OSB/1 type, but the tolerable humidity is slightly higher at 85 percent.

OSB/3

The OSB/3 boards are also used for load-bearing structures, but are offered here for wet areas. They have a significantly better resistance to all forms of moisture and can therefore be used effectively in this area. They are even waterproof and are therefore often used for bathroom floors or saunas.

OSB/4

OSB/4 represents the highest quality standard among the panels and is offered for the same purposes as OSB/3, but is even more robust and resistant to bending. With this type you can theoretically accomplish anything you imagine in this area.

OSB/3 and OSB/4 are the typical boards that you can easily find in numerous hardware stores in Germany and Europe. OSB/1 boards can usually only be found on the Internet, while OSB/2 boards on offer are usually remaining stock that are still waiting for buyers in the warehouses of various suppliers. OSB/3 and OSB/4 are also the boards with the highest quality and offer the best conditions for robust building projects. For this reason, OSB/4 boards are also the ones with the highest purchase price.

Tip:

An alternative to OSB are so-called ESB boards. These are a further development of OSB panels, for which fresh wood is used, which reduces emissions and ensures a he althy living environment.

Dimensions and sizes

Although there are different types of panels, they are offered in the same dimensions due to their simple production method. If you start with the strengths, there are many sizes available that are perfect for your own project. The panels are manufactured in thicknesses from 6 mm to 40 mm, and these variants can be ordered primarily on the American market or from specialist retailers in Europe. The following sizes are part of the offer in hardware stores or online shops:

- 12mm

- 15mm

- 18mm

- 22mm

- 25mm

These are the typical sizes used for the plates. In comparison, an OSB board with a thickness of 40 mm costs between 25 and 30 euros per square meter, which mainly depends on the quality and whether it is sanded. Sanded OSB panels are usually a lot more expensive. In addition to the sizes, the dimensions are crucial for the price and the possible uses of the plate. The most common plate dimensions therefore include:

- 250 cm x 60 cm: Costs per panel around 8 euros

- 250 cm x 62.5 cm: Costs per plate around 9.50 euros

- 205 cm x 67.5 cm: Costs per plate around 7.50 euros

- 125 cm x 250 cm: Costs per plate around 15 euros to 35 euros

- 120 cm x 60 cm: Costs per plate around 10 euros

- 205 cm x 62.5 cm: Costs per plate around 8 euros

- 205 cm x 92.5 cm: Costs per plate around 7.50 euros

- 125 cm x 62.5 cm: costs per plate about 4.30 euros

These prices only apply per piece, the price per square meter is of course completely different. However, you still have an overview of what finished panels cost and the sizes in which they are available. This makes the selection much easier. If you need other sheet sizes, you should contact a dealer who can supply cuts.