- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

Silicone resin plaster is a finishing plaster and can be used indoors and outdoors. It is made of synthetic resin and a silicone resin emulsion. This emulsion makes the plaster more permeable to water vapor and therefore open to diffusion. This is also an advantage of the type of plastering.

Advantages at a glance

Silicone resin plaster is very versatile and has a whole range of advantages. Below:

- can be applied to all mineral and organic substrates

- Open to diffusion, therefore positive influence on the indoor climate

- well insulated, therefore reducing heating costs possible

- durable and robust

- water-repellent

- reduces the risk of mold, fungus and moss formation

- Easy to apply, can also be used by laypeople

- Insensitive to weather influences and chemical influences, such as driving rain, air pollution and acid rain as well as mechanical stress

- can be deleted

The advantages are clear and make the silicone resin plaster an all-rounder whose properties make it suitable for a variety of uses.

Disadvantages of silicone resin plaster

Although plaster has many advantages, it is not without potential disadvantages. These include:

- dries comparatively slowly

- Color selection limited compared to synthetic resin plasters

- relatively high price compared to mineral plasters

- is not subject to any standardization regarding silicone content

So that the last point does not become one of the disadvantages, you should be careful when choosing. The proportion of silicone emulsion is not fixed, so it can vary greatly from product to product. This also affects whether and how open the plaster is to diffusion. If you want a high level of diffusion openness, you should pay close attention to how high the silicone content and vapor permeability is when making your selection.

The application prepared

The application of the silicone resin plaster is very simple and, as mentioned, can also be easily done by laypeople. It is important that the surface is first prepared accordingly. This includes thorough cleaning. The substrate should have the following properties:

- free from grease, dust, moss, loose components and other contamination

- dry

- prepared with appropriate depth base

We recommend using a water pressure cleaner or a sandblaster to clean the walls. If water was used for cleaning, the surface must then dry thoroughly. When using a sandblaster, the sand must be removed by vacuuming and sweeping before a deep primer and then plaster are applied. If a deep primer was used, this must also dry first before the finishing plaster can be applied.

Apply

Silicone resin plasters are available already mixed. So they don't have to be touched and tied first. The application is then carried out in the following steps:

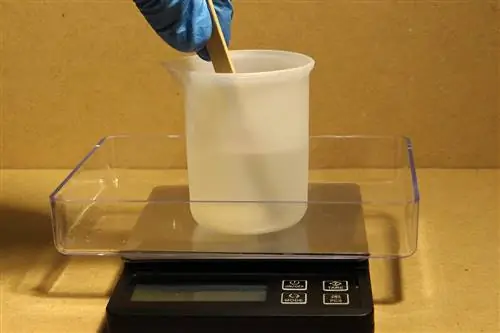

- The plaster is stirred well until a homogeneous mass is formed and no more lumps appear. An electronic stirrer is ideal for this.

- The plaster may need to be diluted with water. The manufacturer's information can be found on the packaging. If a mixture with water is necessary, the plaster should be stirred well again.

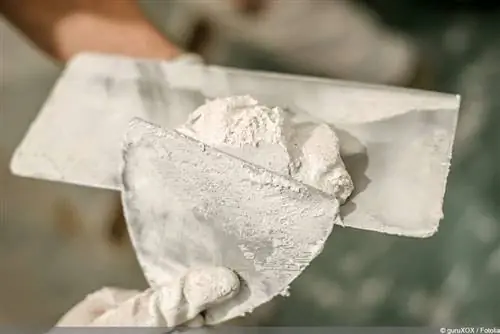

- The plaster is removed from the bucket with a plastering trowel and applied to the wall. It is then smoothed out with a smoothing trowel.

- In order to achieve an even result and an even distribution, the plaster can be removed again with a grape brush. The profiles on this utensil make it easier to achieve consistent thickness.

- Depending on the weather, i.e. temperature and humidity as well as possible precipitation, the plaster needs several days to dry completely. As a rule, two to three days should be expected. In dry weather and sunshine it naturally dries faster than in occasional rain.

In addition to the even distribution, the thickness of the plaster layer should also be taken into account. This depends on the plaster and the surface. How thick the plaster layer should be can be found in the manufacturer's information.

Tip:

The plaster should be applied at temperatures between 5 and 30 °C, then it can be spread easily and dries as quickly as possible.

Paint

Once the plaster has dried, it can be painted. Silicone resin or dispersion silicates are ideal for painting. Basically nothing needs to be taken into account. It is again important that the surface is clean and dry. It therefore makes sense that the plaster is painted as quickly as possible after application. Otherwise, dirt could build up on it and require cleaning before applying the paint.

Painting is always advisable as it increases the durability and resistance of the plaster and prevents some components from escaping. Of course, you should also make sure that the color you choose allows water vapor to pass through and thus has a positive effect on the room climate.

Price

As already mentioned, silicone resin plaster is a little more expensive than, for example, mineral plaster. For 25 kilograms of the already mixed plaster, around 70 euros are due, which is twice the purchase price for mineral plasters. Added to this are the costs of painting. Since the plaster proves to be very durable and is durable and robust even on heavily used surfaces, it often represents a cost-effective alternative in the long term. Since it does not have to be renewed frequently, it not only saves money in the long term, but also a lot a lot of effort.

It should also be noted that silicone resin plasters can usually be applied more sparingly than mineral variants. Since a thinner layer of silicone resin plaster is sufficient, lower material consumption can be expected. Due to the high durability, repairs are also required less frequently. This can quickly put the price difference into perspective.