- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

However, creating a concrete pond is very labor-intensive, time-consuming and, depending on the size, quite expensive. In return, you get an extremely robust pond that will easily last for decades to come. In addition, concrete offers a maximum of flexibility in terms of the shape and size of the pond. Regardless, the costs can be kept relatively low because you can easily create a concrete pond yourself.

The choice of location

If you want to plant the concrete pond, the pond should be created in a location where there are optimal conditions for the planned plants in terms of light and protection from wind and rain. If you also want to keep fish in the pond, you should also make sure that at least part of the pond is in the shade, otherwise the water could heat up too much in hot summers. With regard to keeping fish, it is also important that the pond is created in a part of the garden where you can easily dig a hole at least 1.5 meters deep. This is especially true if you want the fish to stay in the pond over the winter, as ponds with lower water levels can freeze to the bottom in harsh winters at the latest, which would mean the death of the fish.

The actual construction work

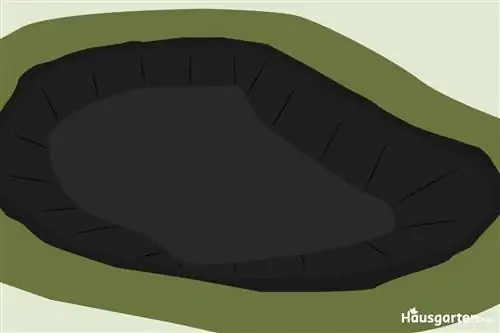

- Once the right location has been found, digging the hole can begin.

- For large ponds, it is recommended to have a small excavator come for this purpose.

- It should also be remembered that due to the thickness of the concrete, the hole must be dug about 20 cm deeper than the actual depth of the pond.

- After the hole has been dug, the subsoil or bottom and side areas are tapped into place.

- This gives the concrete pond support and no loose soil can fall into the still liquid concrete.

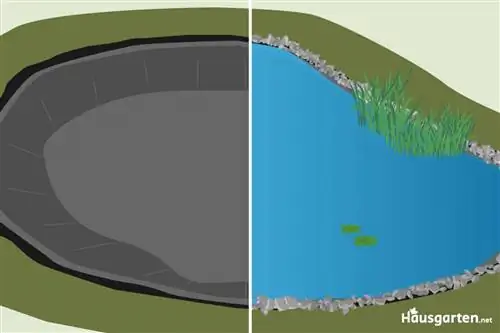

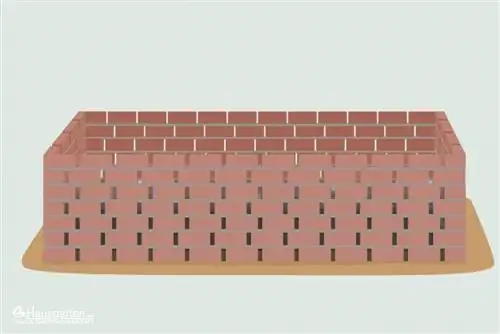

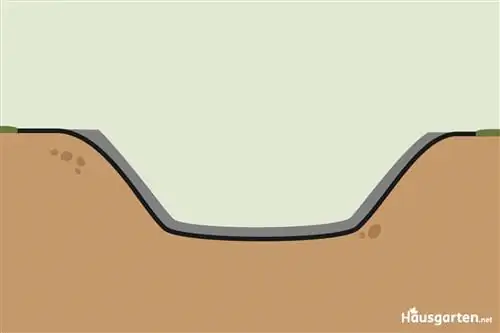

If the sides are gently sloping, the hole itself could now be filled directly with concrete. It should be noted that many pond builders tend to line the hole with pond liner beforehand so that the concrete is not attacked by the wet soil that surrounds it. The film also offers a certain degree of protection from the cold. However, if the sides of the pond slope very steeply, formwork should be built, otherwise the liquid concrete would simply flow to the bottom of the hole.

With regard to the gradient of the pond, it should also be noted that absolutely vertical side walls are possible with the help of formwork. However, this is clearly not recommended, as the ice that forms in the pond in cold winters would put so much pressure on the sides of the pond that, in the worst case scenario, they could burst. Therefore, the sides should definitely be concreted at an angle so that the ice can spread better and therefore exert significantly less pressure. If you are not afraid of completely emptying the concrete pond every year in winter and refilling it again in spring, you can create a pond with straight walls without hesitation.

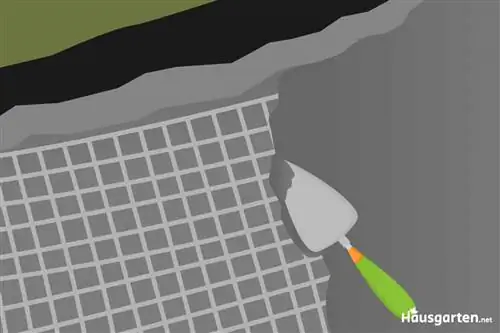

With regard to the concrete itself, it should be noted that for large ponds it must be reinforced with a special insert made of steel or a fiberglass or synthetic fiber fabric, otherwise it could form cracks. In addition, the concrete must be permanently protected from the sun and continually moistened during the setting period, otherwise it could dry out too much, which would again promote the formation of cracks. For moistening, fabric lengths that can be dipped in water from time to time or sprayed regularly are suitable. If formwork was used to build the pond, it may only be removed once the concrete has completely hardened. Finally, it should be noted that at least one unused concrete is ideally poured in a single operation, which is why you should order a concrete mixer truck depending on the size of the pond.

Sealing the concrete pond

During the hardening process and in the days afterwards, the concrete releases limescale. This lime must be removed without leaving any residue at the latest if you want to keep fish in your concrete pond. To ensure that the concrete is absolutely waterproof and definitely cannot release any more limescale, it should be sealed with a multiple coat of special paint after thorough cleaning. This paint should of course be waterproof, frost-resistant and completely non-toxic. However, the concrete should be primed before painting so that the paint can adhere perfectly. As an alternative to paint, you can also use conventional pond liner, which is laid out flush and wrinkle-free throughout the entire concrete pond. In addition to conventional foil, there is also so-called liquid foil that can be used to paint the concrete. Even with liquid foil, the concrete should be primed before painting.

You can also find various sealing slurries in specialist shops that are also suitable for sealing the concrete pond. However, care should be taken to ensure that the sludge as well as the paints, sealing waxes and foils are free of toxins and that they cannot release any unpleasant ingredients into the water. Finally, it should be noted that sealing should be done as meticulously as possible, as leaks are difficult to repair afterwards once the pond is planted and filled with water.

What you should know about concrete ponds soon

Creating a concrete pond may at first seem extremely complex, time-consuming and extremely expensive due to the relatively high material requirements. However, the effort and costs are worth it, as a professionally constructed concrete pond is almost indestructible. For this reason, you should definitely give yourself enough time when planning, especially since major changes can no longer be easily made to a finished concrete pond.

Advantages

- The wear and tear is very minimal.

- Weather influences have no effect on the material.

- And even if animals swim in it, the concrete will not be damaged in the long term.

Disadvantages

- However, in a particularly cold winter, the concrete can crack.

- These need to be repaired, which can be very time-consuming if the pond is very large and well filled with plants.

- To avoid cracks, the concrete must be reinforced.

This means that a special concrete insert is required, usually made of steel (reinforced concrete). Glass fiber or synthetic fiber fabrics can also be used. All in all, this is quite complex and also expensive. You should have practice in processing and using the structural steel mats required for stabilization, it's not that easy.

Structural changes to a concrete pond are almost impossible to achieve. Then you have to use a jackhammer. In addition, the concrete must be protected from dissolution by the acids contained in the water using a coat of paint. Depending on the color, this coat needs to be renewed every few years. This means that the pond has to be completely cleared, which can be an enormous effort.