- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

Using formwork blocks to support an embankment or slope is a long-term solution for stabilization. Our guide shows how to do this and what to pay attention to.

Advantages of formwork blocks

Slopes are often visually appealing and can be wonderfully planted. However, there is a risk that they can be eroded by heavy rain or meltwater. To prevent this, appropriate fastening must be carried out. Formwork blocks are ideal for this. The advantages of such a wall are:

- plantable

- also suitable for very steep embankments due to reinforcement

- low cost

- high stability

- can be set up offset

- durable construction

- variable optics and design options

One potential disadvantage, however, is that the effort required to create it is comparatively high, at least with regard to the foundation. However, once this is finished, the remaining work steps are simple and can be carried out without any problem even without experience or great manual skills.

Preparations on the slope

In order to intercept the embankment, appropriate preparation is required. The following utensils are necessary for this:

- thread

- Measuring tool

- Mini excavator

- vibration plate

- Spade

- Staves

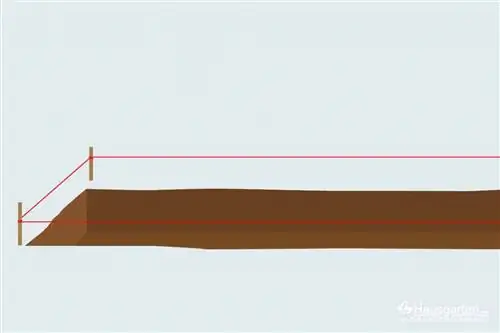

Set out measurements

Depending on the size or width of the formwork blocks, the corresponding dimensions of the foundation must be marked out. This serves as a guide for digging the earth. It is recommended that the foundation be 40 centimeters wider than the dimensions of the stones.

Dig the foundation

The earth can now be removed with a mini excavator. The foundation should be at least 80 to 100 centimeters deep. On particularly steep slopes with little planting, the wall can also be higher. In these cases the foundation should be deeper.

Remove foreign bodies

Annoying foreign bodies, such as large stones and roots, should be removed from the pit. For roots, cutting or parting is sufficient.

Compact soil

When the preparatory steps are completed, the bottom and walls of the excavated pit must be compacted. The best and easiest way to do this is with a vibrating plate. This results in stable surfaces that are ideally prepared for the following steps.

Tip:

The outlined outlines can be cut with a spade. This creates even clearer limits. The equipment required for excavation and compaction can be rented from hardware stores, among others.

Create foundation

Once the pit for the foundation has been dug and compacted, filling can take place. The following materials are required:

- Concrete

- coarse gravel

- vibration plate

- Sand

- Split

If these funds are available, the filling of the excavated pit can begin. The following procedure is recommended:

gravel

The coarse gravel is first entered as the base of the foundation. It should be placed about a quarter as high as the depth of the foundation. For a meter that would be 25 centimeters. This first layer is then compacted and straightened using the vibrating plate.

Split

Fine grit serves as the second layer. This can also be a quarter of the total depth and is in turn compacted with the vibrating plate.

Sand

The third and final loose layer is sand. This trickles down between the gravel and grit as it is filled and compacted, making the base stronger and more durable. Cavities are filled and closed.

Concrete

The end of the foundation is concrete. This is drawn flat after pouring so that a flat surface is created.

Tip:

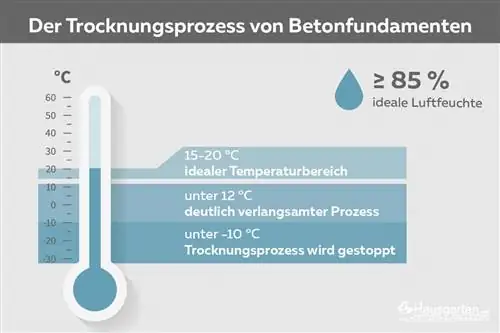

The work should be carried out by at least two people and should take place on a dry but not too warm day. Around 20 °C is ideal. If it rains or is exposed to strong sunlight, the concrete should be covered with a tarpaulin that is not directly on the surface. This promotes the drying process.

Concrete drying time

When the concrete is completely dry, the formwork blocks can be placed. Depending on the dimensions, temperature and humidity, the process of complete drying can take a few days or several weeks. Comparatively dry and warm weather is ideal as the concrete layer does not dry too quickly and no cracks form.

However, this danger also exists when the fresh concrete is exposed to direct sunlight. A protective cover is therefore useful both in the rain and in summer. However, the tarpaulin should not lie directly on top of it, but should be at a distance of ten to twenty centimeters. Fixing it to posts is well suited. During heavy rain, the water should be removed regularly to avoid tearing.

Apply formwork blocks

Aligning and applying the formwork blocks themselves is comparatively easy and quick after these preparations. Only the following points need to be taken into account:

Align

Regardless of whether it is a straight or curved wall made of formwork stones to fix the slope, the individual elements must be set up appropriately. One of the things that helps here is a mason's cord that can be stretched as a guide.

Fixing

When the first row is in place and aligned accordingly, the wall can be increased to half a meter layer by layer.

Fill

When this height is reached, the formwork blocks are filled with concrete. Due to the quantity and distribution, the concrete can dry and harden relatively quickly. Under optimal weather conditions, three days to a week are enough. Again, it may make sense to use a tarpaulin as protection in very humid or extremely warm weather or in direct sunlight.

Reach height

In order to complete the desired height of 100 to 120 centimeters, the remaining layers are applied and also filled with concrete.

Cover

The cover stones are placed as the top layer. They form a secure seal and offer protection against the effects of the weather.

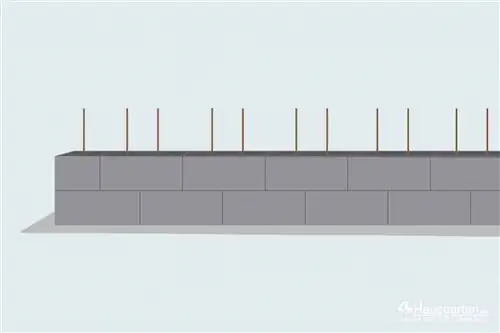

Use rebar

Another variant of using formwork blocks is the additional use of reinforcing bars. These give the wall additional stability, but also increase the effort and increase the costs.

They are inserted into the foundation and used as a framework for the hollow stones. They can therefore be useful on very steep slopes, but are not always necessary.

Tip:

Reinforcement should be used especially if the embankment is only covered with a few plants. Because then a landslide must be expected during heavy rainfall.

Design options with formwork stones

A straight wall made of formwork blocks is comparatively quick and easy to build. However, this is by no means the only variant that is possible. Possible options include:

Walls built in stages

If several rows of different heights are built with the formwork blocks, interesting variations result. If the first row is 40 to 60 centimeters high, it can serve as a bench, while the second and third rows are planted at 100 and 150 centimeters.

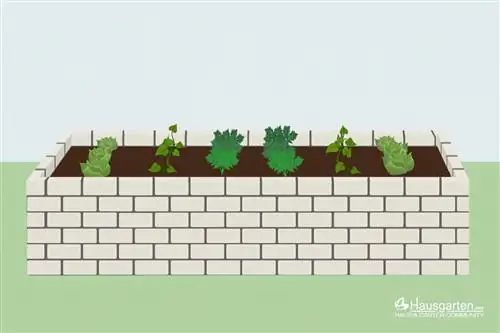

Planters

Formwork blocks with planters inserted can significantly change the look and make the wall more natural. They also offer other options for planting in the garden. Climbing plants or plants with hanging shoots are particularly suitable. It is also possible to have a herb garden or grow berry bushes.

Odd course

Formwork blocks have grooves and joints on the edges. Therefore, it is difficult to achieve an odd course. However, with small changes, a zigzag line can still be created, for example.

Color design

If you prefer a color change, you also have a selection available. Below you will find the following options:

- Paint for exterior walls

- Paint

- Mats in wood or stone look

- Plastering

- Disguise

The only thing that needs to be taken into account is that the materials are weatherproof and can adhere to the formwork blocks.