- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

Previously reserved primarily for inexpensive functional buildings, the flat roof has also enjoyed great popularity in residential and representative buildings since classical modernism from the 1020s. Its structure is just as varied as its use. Here we explain the most common flat roof constructions and explain their advantages and disadvantages.

The general structure

Like all other roof shapes, the flat roof must generally meet three basic requirements. These can be achieved by one and the same component of the constructive structure, but can also clearly “stand in the way” of one another.

Load capacity

Every flat roof structure must be strong enough to absorb the following loads and transfer them safely to the supporting components, i.e. walls or supports:

- Construction - i.e. the weight of the roof itself

- Precipitation - the weight of rainwater and especially snow

- Traffic loads - depending on the type of roof use, either craftsmen for maintenance, or - if used as a roof terrace - people, furniture, plants, etc.

Thermal insulation

For heated buildings, the Energy Saving Ordinance ENEV requires a minimum standard of thermal insulation for the flat roof in order to limit the amount of energy lost through the roof surfaces. Although this is not necessary for unheated buildings, depending on the use, a minimum insulation to prevent condensation in accordance with DIN4108 may be necessary.

Sealing

Lastly, the flat roof should of course protect against the adverse weather conditions, i.e. wind and precipitation. For this purpose, the structural design must provide for a dense level. As a rule, this must be designed in such a way that problems that arise, such as a blocked drain or a defective gutter, do not immediately lead to water damage in the construction.

Advantages and disadvantages

Finally, the main advantages and disadvantages of flat roofs should be clearly summarized here:

Advantages

- Low installation height

- Easy to use on top (e.g. roof terrace)

- Reserved to invisible appearance

- Production can be achieved quite easily by installing insulation and sealing horizontally

- No lost attic space underneath, as the room is horizontally closed at the top

Disadvantages

- Slow water drainage due to no or low inclination

- In the event of leaks, water quickly enters the construction

- Internal drainage complex and prone to failure

- No snow slipping due to lack of slope

- No self-cleaning effect, as the slowly draining rainwater has little rinsing effect

Tilt

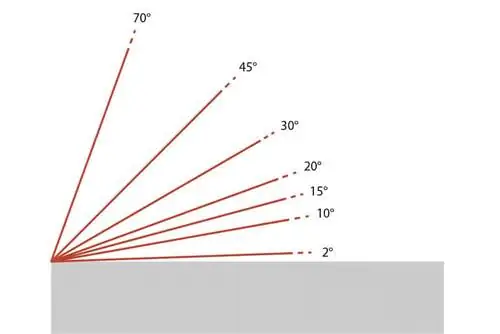

Even if the flat roof is flat, that doesn't automatically mean that it can't have a slope at all. Even the opposite. If the specifications of the flat roof guidelines are followed when constructing the flat roof, the roof must have an inclination of at least two percent towards the drainage points - roof drains or rain gutters. Either the entire roof can be sloped, or only the sealing level is provided with the slope, for example via tapered sloped insulation on a completely horizontal construction level. This tendency leads to rainwater being directed specifically to the draining components. The inclination dimension, which appears to be quite high, also takes into account the fact that deviations can always occur during execution. If the slope is too low, water pockets would form even with small differences in level, in which rainwater would permanently stand and put a strain on the structure. At the top, the demarcation of the flat roof from steeper roof shapes is not clearly defined. From an inclination of around three to five degrees, people no longer speak of a real flat roof, but rather of a flat-sloped roof.

INFO:

The specified minimum inclination does not necessarily have to be adhered to. Real flat roofs with a zero degree inclination are always being created. However, the slope value reflects the experiences of flat roof builders and is intended to help prevent moisture damage as much as possible

Classic building materials

Unlike various other roof shapes, the flat roof is quite limited in terms of the building materials used to create it. This is primarily due to the design challenges of the minimal inclination and possible use of the roof area. The structure, insulation and sealing must adapt to this and respond to the challenges of these peculiarities.

Structural structure

The following supporting structures have been established:

- Homogeneous reinforced concrete slab

- Steel or concrete beams with suspended concrete elements

- Wooden beam with wooden covering as a load-bearing level

- Steel beam with wood or metal covering (then usually trapezoidal sheet metal)

Insulation

Proven insulation options are:

- Foamed plastics as classic insulation materials for laying on flat surfaces, e.g. reinforced concrete slabs or wooden coverings

- Foam glass as a flat covering, see above

- Mineral wool, cellulose insulation and other soft insulation materials for installation in cavities between load-bearing elements

SPECIAL CASE:

Sandwich elements

Here, foamed plastics are used directly with a trapezoidal sheet as a combination of insulation layer and flat supporting structure.

Sealing

When it comes to sealing flat roofs, there are ultimately only two common variants:

- Film - plastic film for bonding to flat surfaces, e.g. pressure-resistant insulation

- Bitumen - bitumen-containing waterproofing membranes that are not glued, but welded on by flame-burning and liquefying the bitumen

Topping

Usually not necessary for the pure function of the flat roof as part of the building envelope, different coverings on the roof can bring various advantages:

- Greening: Delay in the release of rainwater, ecological added value, visual enhancement

- Gravel: mechanical protection of the seal, load as protection against wind suction, UV protection of plastic and bitumen seals

- Walking surfaces: To use the roof surface as a terrace, as a slab covering or wooden grid can be produced analogously to terraces on level ground

Construction Principles

Now that you know the essential requirements for a flat roof, as well as the catalog of common components, it is now important to combine both into a functioning overall construction. Despite what initially appears to be a very high number of possible combinations, there are actually only a few general systems according to which a functioning flat roof is usually created:

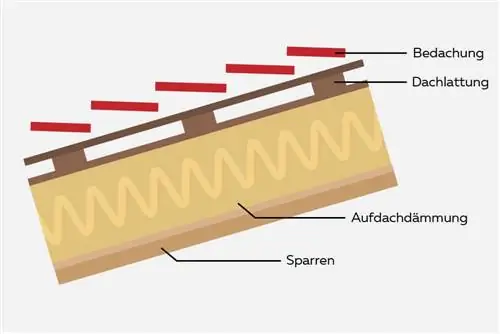

1. Roof insulation

In this classic and simple form of flat roof, the components are simply stacked on top of each other. At the bottom is the supporting structure, i.e. the concrete slab or the wooden covering on a support level. This is followed by the insulation layer. This must be so pressure-resistant that it can accommodate the following components as well as a possible snow load and, if necessary, withstand use of the roof. The seal is now applied to the insulation layer as a flat substructure. It protects the entire structure, as well as the building covered by the flat roof. An individual covering can now be applied to the seal, or the seal can remain as the top functional end of the construction.

1b. Special case of inverted roof

A special form of the flat roof structure just described is the so-called inverted roof. Here, the insulation is not installed under the protective seal, but rather placed on top of the seal. The seal is therefore located directly on the load-bearing level. For this roof structure, the insulation layer must be laid without any joints or gaps in order to prevent the ingress of heat-conducting rainwater as much as possible. In addition, the insulation itself must be able to withstand constant moisture. This construction is usually completed by a protective membrane and a gravel layer to secure the insulation in its position.

NOTE:

Commonly used in the 80s and 90s of the last century, this construction can still be found in existing buildings. However, it is rarely rebuilt due to the insulation difficulties.

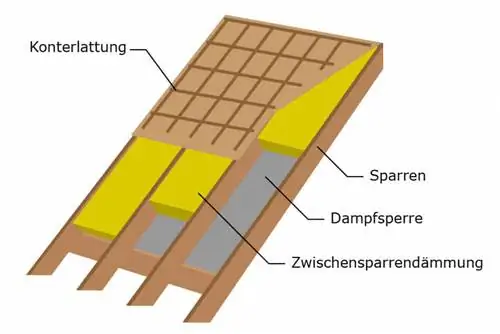

2. In-roof insulation

If the flat roof is made from a support layer with panel materials on top, it is possible not to lay the insulation on top, but to insert it between the supports. The advantage is obvious: a significantly reduced installation height due to the no dimension of the insulation layer. On the other hand, the insulation must be secured at the bottom to prevent it from falling out, so a suspended ceiling with trickle protection film and clamping battens cannot be avoided. In general, in-roof insulation is only suitable for wooden structures, as the wood itself has a certain insulation value. Steel or concrete beams, on the other hand, would create blatant thermal bridges between the individual insulation packages with all the resulting problems.

3. Under-roof insulation

For the sake of completeness, the under-roof insulation should be mentioned here. Here an existing roof is insulated from the underside. This can be done either by gluing and covering flat insulation materials, or by providing additional battens between which the insulation is installed. However, since the insulation can only be extended up to the walls supporting the structure, it represents the worst possible option and is usually only found in the renovation of old buildings. Because its advantage is clearly that it can be installed without having to open the existing roof or completely dismantle it.

The edge of the roof

On flat roofs, special attention is paid to the edge of the roof. The flat roof can either be provided with a roof overhang or hidden invisibly behind an attic, i.e. a surrounding wall. Depending on the desired solution, this places special demands on the edge of the roof:

For roof overhang

- External drainage via rain gutter on one side or all around

- Roof slope inclined outwards towards the gutter

- Run the seal over the inlet plate into the gutter

- If covering on top of waterproofing, provide water-permeable edge strips, e.g. gravel strip

NOTE:

Of course, a flat roof with an overhang can also be drained via internal drains. However, these are rarely used because they are more prone to failure than a gutter and also require numerous roof penetrations. The first choice is therefore usually the external gutter, over which the water simply runs out and drips in the event of a blocked downpipe.

At Attica

- Run the seal all around the parapet upwards

- Sealing height according to DIN at least 15cm above the top edge of the covering

- Observe the bend radii of the seal in the valley of the roof area to the parapet and provide an insulating wedge

- Upper sealing over clamping profile and overhang plate

- Drainage on the inside via roof drains, align the gradient to the lowest point

- At least two drains required, alternatively emergency overflow as a second drain

- Protect the upper side of the parapet against water, e.g. by metal sheeting