- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

Scratch plaster is open to diffusion and thus enables a natural exchange of moisture. This prevents stagnation, reduces the risk of mold and can also have a positive effect on the indoor climate. In addition, it has a high heat storage capacity and is also impact-resistant and self-cleaning. Together with the ease of application and the variety of possible colors, this form of fine plaster offers convincing advantages.

Select scratch plaster

The plaster type is available in different versions. The first thing that is important is whether it should be applied inside or outside - depending on this, the appropriate plaster must be chosen. Further differences can be found in the color and composition. Real scratch plaster usually has to be mixed with water and can be tinted by adding different colors.

Types that have already been mixed and tinted are more often silicate scratch plasters or synthetic resin plasters, which no longer offer the full range of advantages mentioned. Silicone resin scratch plasters can have a scratch plaster structure as rubbing plaster, but their properties also differ from mineral fine plaster.

If you want real scratch plaster, you should pay attention to the exact name and only have to decide according to the use for inside or outside as well as the grain size and, if necessary, the color.

Tip:

Rubbing plaster and window plaster also have a similar structure, but they differ in their properties and in the application or processing.

Prepare surface

Before the plaster can be applied, the surface must be prepared accordingly. Dust, moss, plant residues or other dirt, but also cracks and moisture can affect the durability of the scratch plaster. Accordingly, the wall must be thoroughly cleaned in advance and cracks repaired if necessary. Water pressure cleaners or sandblasters can be used for cleaning. Please note that the surface must then dry sufficiently. Depending on the weather, this may take several days. After using the sandblaster, the wall should be swept and vacuumed to thoroughly remove dust and grains.

Only then can the plaster or, if necessary, the plaster base be applied.

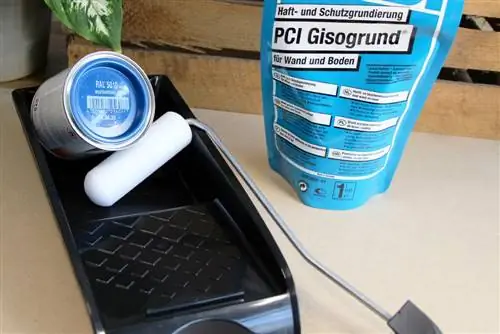

Users needed

In addition to the scratch plaster itself, other utensils and one or two tools are also required for application and painting. Below:

- Mason's doll or mortar bucket

- Electric mixer or stirring attachment for the drill

- Facade filler

- Brush and hand brush

- Smoothing trowel

- Grapewrap

- Nail board or fine plaster scraper

- Safety clothing, gloves and glasses

Prepare the plaster

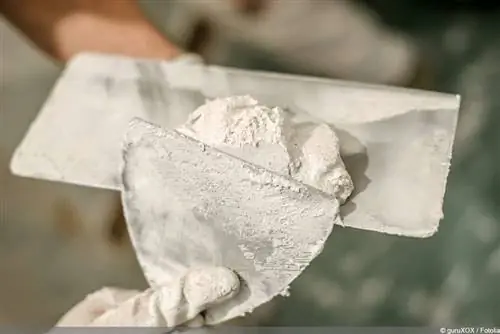

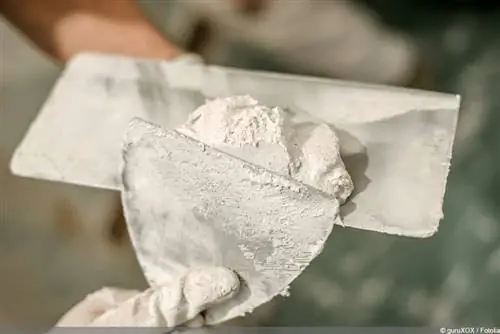

If the fine plaster has not yet been completely mixed, it must be mixed first. To do this, proceed as follows:

- The dry plaster is placed in a mason's trowel or a mortar bucket and mixed with water according to the manufacturer's instructions.

- The plaster is now stirred with an electric mixer until a lump- and nodule-free, homogeneous mass is created.

- The plaster is allowed to swell for five minutes and then stirred thoroughly again.

Depending on the temperature and humidity, there is still about half an hour to three quarters of an hour left to process the scratch plaster after preparation. Afterwards the plaster becomes too stiff to be easily applied.

Tip:

Since the mixed plaster dries so quickly, only small amounts should be prepared at a time. Otherwise there will quickly not be enough time left to process it accurately.

Apply

The plaster is applied with a facade filler, smoothing trowel or steel trowel. It should be 1.2 to 1.5 centimeters thick. However, the thickness of the application depends on the type and grain size of the scratch plaster. As with mixing with water, the manufacturer's instructions should be taken into account here. The plaster is smoothed with the smoothing trowel. In order to get a really even result, a grape brush should also be used to smooth the surface. With the help of these and their profiles, the excess can be removed and any remaining “dents” can also be compensated for.

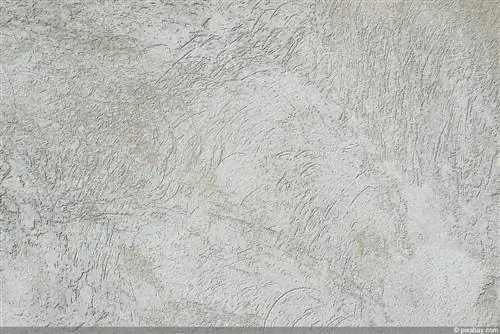

Structuring

Immediately after application and smoothing, the fine plaster does not yet have a scratch structure. This still has to be created by structuring the surface accordingly. This is only possible after an initial drying period. The surface should be scratched with a nail board. If the plaster is still smearing and the excess does not fall down dry but collects on the protrusions of the nail board, sufficient drying has not yet been achieved. Again depending on the temperature and humidity, achieving the right consistency can take around three to six hours. However, the condition can occur more quickly in very hot and dry weather. Therefore, you should check at least once an hour whether painting with the nail board is already possible.

Apart from the right time, the procedure for processing the plaster is also crucial. The nail board is moved over the surface with light pressure in even, circular movements. Coarser elements are loosened and torn out. While scratching, care should be taken to ensure that the plaster does not become too thin. A thickness of eight to ten millimeters is ideal.

Mending

Although scratch plasters are very durable and impact-resistant, weak points can become apparent after a few years. Improper application or inadequate cleaning of the surface before application can also lead to plaster falling off. In this case, the following steps are recommended:

- Take off the loose plaster lightly and remove it thoroughly. Smaller components can be swept away with a hand brush or brush.

- Paint the cleaned area with deep primer and let this layer dry.

- Put the plaster into the hole and proceed as described above when smoothing, letting it dry and roughening.

When repairing, it is also important that the plaster is initially applied very thickly and extends slightly beyond the damaged area at the edges. In this way, it can still be removed when scratching and is seamlessly connected to the old plaster.

Cleaning

One of the advantages of scratch plaster is that it continuously “trickles down”. In addition to the components of the plaster, dust and other dirt also fall off. The scratch plaster is, to a certain extent, self-cleaning.