- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

LED-based plant lighting is a valuable and very useful accessory for many hobby gardeners. It's just a shame that a plant light like this isn't exactly cheap in stores. Depending on the size and design, this can quickly add up to several hundred euros. It will be significantly cheaper if you build the LED lighting yourself. It takes work and requires some knowledge, but it's definitely worth it.

Plants and light

Light is essential for plant survival. Without light, photosynthesis and therefore growth cannot take place. Of course, not all light is the same. Sunlight, for example, covers a wide range of colors that we cannot normally perceive but that are of great importance to plants. When building an artificial light source from LEDs, this color spectrum must therefore be reproduced. Building light and red light are of particular importance here. Blue light supports the plant in sprouting and generally in growing. Red light, in turn, plays a major role in the formation of flowers and fruits. The decisive factor for these so-called color spectra is the respective wavelength range in which they radiate.

LED principle

LEDs have been completely transforming the lighting market for a few years now. No wonder: the small light-emitting diodes are not only significantly more efficient than the good old light bulb and require much less electricity, but can also be combined in a variety of shapes. It goes without saying that, given these conditions, they are ideal for effective plant lighting. If you build your LED plant light yourself, individual solutions that are tailored precisely to your needs are possible. However, for this to work, LEDs have to be specially wired, which requires at least some basic electronics knowledge. You also absolutely need a power supply that converts the alternating current from the socket into direct current.

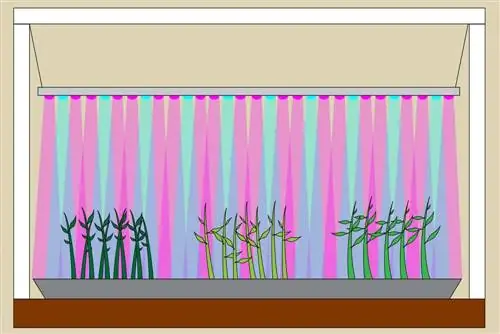

LED Bar

The simplest construction of LED plant lighting is certainly that of the light strip or bar. Its shape is somewhat reminiscent of fluorescent tubes. Like this one, it hangs freely in the room - as a plant light, of course, directly above the plants that it is intended to illuminate. The LEDs are arranged in one or more lines. In principle, the light-emitting diodes can be arranged according to very different principles, for example in the form of concentric circles. However, we want to concentrate exclusively on the linear arrangement here, because an LED bar can be built relatively easily even by relatively inexperienced people. The end result should be an LED bar with two parallel lines and a length of one meter.

Material and tools

All the materials we need for our self-made LED bar are easily and inexpensively available at hardware stores or electronics stores. We differentiate between the electronic components (LEDs, power supply, resistors, cables) and the construction elements such as the support strips and the suspension. You also need common tools that you usually already have.

LEDs

LEDs are the core elements of our LED bar. We use seven royal blue and 15 deep red LEDs, each of which is already mounted on a circuit board. You must meet the following requirements:

- Version: High Power LED

- Power: 3 watts

- Wavelength range blue: 490 to 450 nm

- Wavelength range red: 700 to 630 nm

The number of installed LEDs can of course be changed individually. The only important thing is that significantly more red ones are used than blue ones.

Tip:

The easiest way is to buy pre-constructed LED chains or DIY kits and save yourself the very complicated wiring, which is almost impossible to do without in-depth knowledge of electronics. We will therefore not go into the connection in more detail.

Power supply

The LEDs are supplied with power via the power supply. It converts the alternating current from the socket into the required direct current. The most important thing when choosing the right power supply is the current strength. For our purposes it should be at least 700 mA. The voltage must be 24 volts or 48 volts.

Tip:

Used power supplies can be found in practically every household in this country. If such a used part is still functional and delivers the required current, it can of course be used. This may save considerable costs and benefit the environment.

Cable

Cables are necessary to connect the LEDs to each other and to the power supply. For example, speaker cables, the so-called twin strands, are recommended here. They should have a thickness of 0.5 or 0.75 square millimeters.

Assembly materials

The following is required for the support structure of our LED bar:

- Wooden top or old table with a width of more than 100 cm

- two aluminum U-profile strips measuring 100 x 3 x 3 cm

- three square profiles made of plastic with a length of 100 cm

- two matching plug-in angles

- two matching mounting feet

- four chains, each 50 cm long

- heat-conducting adhesive pads

- two spacers or spacer screws with a length of approximately 15 cm

- Screws and nuts in different sizes

- Tool

A drill and metal drill are absolutely necessary for building our LED bar. Alternatively, you may be able to use a cordless screwdriver with a metal drill attachment. You will also need a screwdriver and possibly a metal or plastic saw.

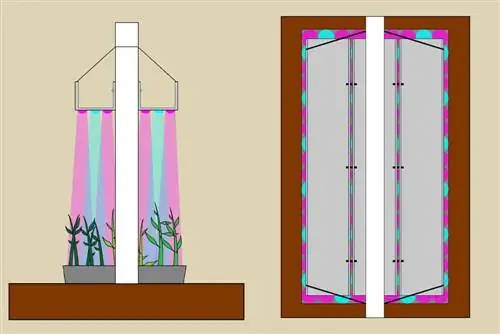

Construction

Setting up our LED bar is incredibly easy. It consists of a plastic frame that is mounted on a wooden board or an old table. The two aluminum profiles, to which the LEDs are attached, hang on chains on this frame. The profiles are guided parallel to each other and kept at a distance using the spacers. The power supply is external and not directly attached to the construction. For example, it can be mounted on the wooden panel. Of course, you can also do without the frame and hang the aluminum profiles directly on the ceiling. However, significantly longer chains are then required. The advantage of the frame is that a special space can be created for the entire structure practically anywhere in the house or apartment. In addition, there is no need to drill holes in the ceiling.

Construction instructions frame

First we build the frame from the plastic square profiles:

- Screw the two matching mounting feet one meter apart on the left and right of the wooden plate

- Place a square profile in each of the feet

- Attach an angle piece to the other end of each profile

- Place the third square profile into the angle pieces and create a connection

- Drill two holes in this profile near the ends

- Insert two screws with nuts into these holes, to which the chains will later be attached

Construction instructions rails

The second step is now to build the actual bar and equip it with the LEDs. You should know that LEDs should be cooled. This cooling is achieved by the U-shape of the two aluminum profile strips. The legs dissipate the heat to a certain extent. The open side of the strips must therefore also point upwards. The LEDs are simply glued to the closed underside. It is best to use heat-conducting adhesive pads, which also promote heat dissipation. Here's how to proceed step by step.

- First drill two holes in each of the two profile strips for the spacers or spacer screws

- Fit the holes with the spacers and screw them together

- The distance between the two profiles should be approximately ten centimeters

Note:

In principle, any number of profiles can be combined with each other in this way. The rule of thumb is: the more profiles, the larger the area that can be illuminated by the LEDs.

Equipped with LEDs

Once the aluminum rails have been prepared in this way, it is now time to equip the undersides of the profiles with the LEDs. These are simply stuck on using adhesive pads. Care should be taken to ensure that the distribution is as even as possible and that the blue and red LEDs are mixed. The connecting cables are simply routed along the underside towards the sides and then led downwards or upwards from there. Since we use a ready-made LED chain or a DIY kit, we don't have to worry about the correct wiring. The cables then simply need to be guided towards the power supply and extended if necessary.

Tip:

When mounting on a wooden plate, it is recommended to also attach the power supply to the wooden plate.

In a final step, all that remains is to attach the chains and hang the finished bar. The chains are simply installed by attaching the last chain link to the screws on the top of the frame and the aluminum profiles. It makes sense to secure them with a nut on both sides. The chain links can also be used to easily regulate the height as soon as the plants below the lighting grow larger.

Advantages of the LED Bar

The LED bar that we have presented here offers an extremely high degree of flexibility. Above all, it can grow with you to a certain extent. LED lighting is particularly suitable for growing or overwintering plants of all kinds in the apartment or house. Depending on the plant, it is also possible to expose it to artificial light all year round - including harvesting fruits and vegetables. The costs for our self-made LED bar vary of course. However, you can assume that you have to invest between 50 and 100 euros. Compared to other plant lighting, this is definitely worth it. LEDs consume very little power, which means you can of course save significantly on electricity costs.