- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

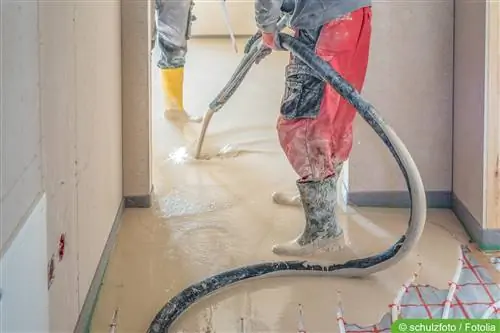

Screed is the basis for many floor coverings. It is durable and easy to care for. However, if the load is applied too quickly after application, it can be damaged, which has costly consequences. We show how long the drying time is.

Until screed is walkable and ultimately resilient depends on various factors. These include, above all, the type of screed and the prevailing temperature. The following guide reveals what is important.

Wet screed - risks

If damp or not yet completely dry screed is loaded, the mass can be displaced at certain points. This manifests itself, among other things, in unevenness. Cracks can also occur.

Compensating for this damage requires considerable effort and can quickly become very expensive. In addition, there are delays that arise from correcting the errors. This makes it all the more important to allow enough time for drying.

Decisive factors

Various influences play a decisive role in the length of the drying time. These include, among others:

- Type and composition of the screed

- Humidity and ventilation

- Temperature

- drying accelerator

- Volume of the screed layer

Only when all these factors are taken into account is an estimate of walkability and resilience possible. In addition, based on these points, a good starting point can be created to shorten the drying time.

Screed type and composition

Calcium sulfate screed dries comparatively quickly. It can be walked on after about three days and, under optimal conditions, can be fully used after about four weeks. This comparatively short duration can be further shortened using drying accelerators.

Cement screed requires more patience. It will only be walkable after a week at the earliest. If there is a very thick layer or a very large screeded area, it can take three weeks until it is walkable.

It takes at least six weeks until you are fully resilient. Again, the larger the volume, the longer the duration.

Climate

Whether laundry or screed is drying, the climate is crucial to the process. This consists of:

- Temperature

- Humidity

- Air circulation

If the temperature is too low, the drying process will not start. The temperature should therefore be at least 13 degrees Celsius. Even then the duration is very long. Temperatures between 20 and 30 degrees Celsius are better, and should be as constant as possible.

At temperatures above 30 degrees there is a risk that the screed will dry out too quickly on the surface and cracks will form.

Note

Similarly, temperature fluctuations can lead to problems and uneven drying.

Humidity and circulation are also important. Moist air can absorb less liquid. If it is also in the room in question, there will be no exchange or removal. Instead, the water in the air can condense back onto the surface of the screed and thus effectively prevent it from drying.

This can more than double the amount of time you have to plan for before walking or loading.

Thickness and size

The thicker and larger the screed layer is, the longer the drying process takes. Because the mass dries from top to bottom. This means that the moisture from the deeper areas must always be transported to the sides and the surface and evaporate here.

For this reason, screed can already appear solid and dry on the top, although there is still a very high level of residual moisture inside.

Calculate drying time

A layer of screed about four centimeters thick requires a drying time of four weeks under optimal conditions. Six centimeters takes eight weeks under the same conditions. At seven centimeters it takes 13 weeks.

How do these values come about? Through laboratory studies and a resulting simple formula.

The basis for this is:

4 centimeters=4 weeks

For each additional centimeter, the number over four centimeters is squared. This results in six centimeters:

- 4 centimeters=4 weeks

- 2 centimeters square=2 x 2=4 weeks

- 4 weeks + 4 weeks=8 weeks

For a seven centimeter thick layer, there is an excess of three centimeters. This results in:

- 4 centimeters=4 weeks

- 3 centimeters square=3 x 3=9 weeks

- 4 weeks + 9 weeks=13 weeks

Note: This information only applies to optimal conditions. If the humidity is high or the temperature is too low, the drying process can be significantly delayed. However, the calculation still serves as a good guide and can prevent problems.

Accelerate drying

There are several ways to shorten the drying time of screed and thus the waiting time until the floor is laid or further work is carried out.

This primarily includes creating the appropriate climate. This can be achieved through various means and measures:

- Install dehumidifier

- Set up fans

- Use a heater or fan to increase the air in the room

- Add drying accelerator

When temperatures are relatively constant in summer, fans are sufficient. They allow the air to circulate better and therefore transport moisture away better. If sufficient ventilation is not possible because the air outside is also humid, dehumidifiers, drying fans or adsorption dryers make sense.

When outside temperatures are low, fan heaters, heaters or other forms of heating can also be useful. However, they should not be aimed directly at the floor, but should warm the air and keep the heat as constant as possible and distribute it evenly. This allows it to absorb more moisture.

Tip:

The necessary equipment can be borrowed from hardware stores, among other places. It's worth comparing providers and the costs of renting or buying.

Difference walkable and resilient

Calcium sulfate screed can be walked on after just three days. However, it should only be put under strain after several weeks. The difference is that when a single person walks on it, only a small amount of pressure is exerted at specific points. The prerequisite for this is that no one jumps or runs on the screed and the load is only brief.

If, for example, a ladder is set up, a pallet is placed on it or the floor covering is applied too early, the weight and pressure will result in compaction and shifting of the mass.

Complete hardening is therefore the basic prerequisite for further work steps.

Tip:

If immediate resilience is desired, dry screed is a practical alternative. These are panels that are laid and screwed or glued into place. Even after gluing, you only have to wait a few hours until the load capacity is achieved.

Measurements for safety

Due to the numerous factors that play a role in the hardening of the screed, the residual moisture should be measured before walking on it and before further stress. There are special devices for this that can also be borrowed.

It is still recommended to have the inspection carried out by specialists.