- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

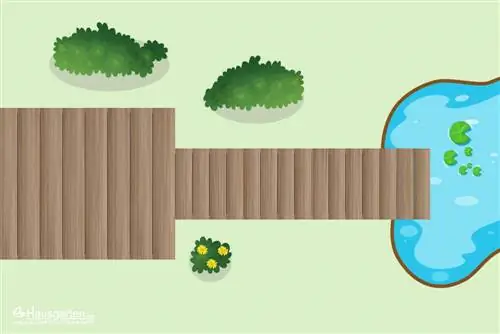

The posts serve as the basis for building a fence or shed. However, their durability is not good if they are simply buried in the ground. It is much more worthwhile to encase posts in concrete, but how do you do it correctly?

Preparation

A wooden post buried in the ground and the later finished structure are exposed to wind and weather as nature's plaything to ensure a certain level of durability. There are a few things to consider when planning to ensure that the later project is successful.

Tip:

It is worthwhile to make markings in advance, as wooden posts once set in concrete can only be removed with a lot of effort.

It is also important to make sure that the temperatures are acceptable and that the soil is frost-proof. There must not be any lines or cables underground.

Material list

A post is quickly set in concrete in your own garden. All tools and materials are available at hardware stores:

- Mortar

- Precast concrete

- gravel

- gravel

- Post

- Water

- Shovel

- Spade

- Hammer

- Spirit level

Hole depth

Universal rules of thumb have been established when setting a post in concrete. The height of the post is related to the depth of the hole. This ensures the stability of the object later on and guarantees a certain level of durability. The minimum depth, however, should be around 80 centimeters. A drainage layer made of gravel or gravel also takes up another 10 centimeters. It lies directly under the concrete layer. In cold areas, a foundation of up to one meter is the rule. The responsible building authority can provide more precise answers and recommendations regarding local conditions.

Types of wood

Numerous local types of wood are suitable for setting in concrete and ensure the stability of the object built with it. There are high-quality posts made from the following types of wood:

- Fir tree

- Larch

- Pine

- Spruce

- Elm

- Whitebeam

- Robinie

- Oak

Regardless of the type of wood you choose, it is recommended to first treat the wood with a wood protectant. Glaze or special wood varnish is suitable for this.

Costs

Without knowing the exact dimensions of the project, no general answer can be given. The more complex the type of installation, the higher the cost, although there is no upper limit. A simple construction keeps costs manageable because basic tools such as spades are already available and not too many materials are necessary.

Further costs arise from concrete mixes, which cost around 15 euros per 25 kilograms. The amount of concrete required can be calculated using a simple rule of thumb and depends on the number of wooden posts.

Rule of thumb:

A hole measuring 30 by 30 centimeters and the usual depth of 80 centimeters can hold around 50 kilograms of ready mix. Since the underlying layer is made of gravel, there are additional costs for a 25 kilogram bag of gravel of just under 5 euros.

Instructions

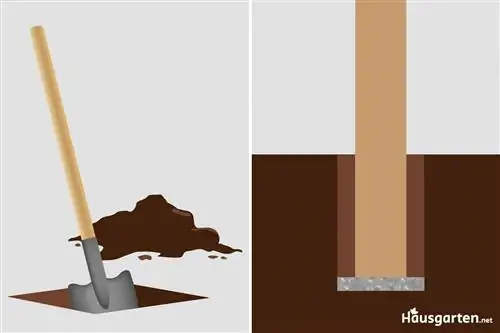

1. After the markings have been placed, the holes must be dug. The depth depends on the construction and the size of the posts. A depth of 80 centimeters is recommended, as this ensures a certain durability and stability of the wooden posts. The cross section should be 30 by 30 centimeters. The turf must be carefully cut off so that it can be covered later.

Tip:

A garden spade is helpful, but a hole spade makes digging narrow holes much easier.

2. Beneath the concrete layer, a layer of gravel or gravel serves as drainage and prevents water from accumulating. The posts must then be placed in the holes.

3. The concrete mix can be mixed with a conventional spade or shovel. A good foundation consists of a 4 to 1 ratio of gravel to cement. How much water you need can be found in the manufacturer's information. A distorted result leads to adverse results.

4. The pit must now be filled with the mortar. The mixture can be compacted using a stick. At this point, a subsequent correction of the posts is still possible. The grass floor can then be returned to its original place.

Alternatives

Casting posts in concrete has proven itself and ensures a long-lasting and stable construction. However, this type of assembly is time-consuming. An alternative is to use special drive-in sleeves, which enable posts to be fixed quickly. This requires pure muscle strength. The construction also loosens over time. This type of installation is therefore less suitable for high fences. Screw-in sleeves have also proven to be particularly effective on softer soils. The sleeves can be screwed into the ground using a rod. If the post base is only screwed onto the foundation, there are no direct points of contact with moisture.

Tip:

In this way, wooden posts are protected from the weather, which extends the durability of the wooden posts.