- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

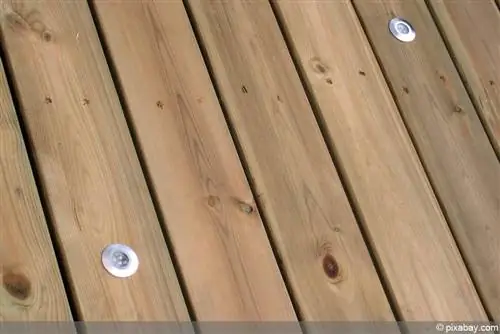

If the decking boards are to be replaced or re-laid, the question of the desired material comes first. A large selection of different types of wood, as well as plastic and WPC, are now available in stores. But what are the differences between the materials and what are the advantages and disadvantages of each?

Wood

The decking made from raw materials is a classic and looks particularly natural. Further advantages of this material are that it is durable, available in many different variations and is also easy to work with. The following types of wood are mainly used for terraces:

- Bamboo (Bambusoideae)

- Bangkirai (Shorea laevis) - Yellow Balau

- Cumaru (Dipteryx odorata) - Tonka bean tree

- Douglas fir (Pseudotsuga menziesii)

- Oak (Quercus)

- Pine (Pinus)

- Larch (Larix)

- Robinia (Robinia pseudoacacia)

The differences between these types of wood lie not only in their appearance, but also in the respective properties of the material. In general, however, the renewable building material has the following advantages:

- natural grain and therefore visually appealing

- long-lasting and durable with appropriate care

- high breaking strength

- Protection of the material possible through simple measures

- easy to edit

- optical diversity

However, the natural material not only has advantages but also disadvantages. These are:

- optical change due to UV radiation and weather

- Formation of splinters, for example due to force influences

- Protective measures necessary for preservation

Which properties the natural material has also depends on the respective type.

Bamboo

Bamboo as a material is not strictly speaking wood, but comes from a grass. It has a fairly light coloring, although this can vary greatly depending on the exact species. The material can come from slow or fast growing bamboo species, which in turn affects the hardness. Slow-growing species produce harder lumber. In general, the floorboards made from this material are comparatively soft and can therefore become damaged more quickly.

In addition, the raw material does not contain any permanent, defensive substances. This means that it must be regularly protected from fungi and insects using suitable means.

Bangkirai

The type of wood with the exotic-sounding name is a hardwood and is often used for floors because it is extremely resilient. The grain is very fine and homogeneous, so visually it is rather inconspicuous. A clear advantage is that this type of wood is naturally highly resistant to fungi and insects and therefore does not require any special protection. However, it tends to crack and should not come into direct contact with ferrous metals, otherwise it will turn a strong gray-blue color.

In addition, special drills are necessary to process the heavy, hard wood; simple wood drills are not sufficient.

Cumaru

Cumaru or Cumarú is a tree from South America that, like Bangkirai, is very hard and resilient. It is only commercially available in small quantities, but is very durable and long-lasting. Due to the substances it contains, it is resistant to fungi and insects even when untreated, which makes care significantly easier. However, processing is difficult due to its great hardness. Special tools and pre-drilling of holes are required during installation. Another well-known name is also tonka bean tree (bot. Dipteryx odorata).

Douglas fir

Douglas fir is often used as an outdoor material, especially in America. It has a medium hardness and can therefore be processed relatively well, is comparatively durable and can withstand the effects of the weather. It also has a decorative grain and exudes a pleasant, albeit pungent, woody smell.

However, applying appropriate protection is recommended.

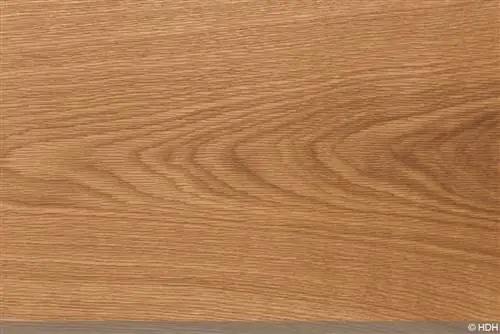

Oak

The term oak covers several different types of oak, such as white oak and red oak. The advantages and disadvantages of the wood as well as its appearance vary accordingly. In general, however, the natural material can be easily processed and treated with protective agents. When attaching the decking, however, care must be taken to ensure that the material can quickly break and tear due to its nature. It is therefore advisable to make preliminary drillings.

Suitable protective products should also be used, as there are significant differences between oak wood when it comes to resistance to harmful influences such as weather, fungi and insects.

Pine

Pine wood has medium to hard strength and is easy to process, so it is versatile and popular. Protection with varnish or glazes is advisable in order to extend the service life and at the same time maintain the light to medium color or to prevent discoloration and staining.

Since pine wood is readily available, the material is also an affordable choice in terms of price. However, when choosing, you should pay attention to which type of pine tree it is. American pines are divided into soft and hard species. If possible, a hard variant should be chosen for the decking, as these are more resilient and durable.

Larch

Larch wood is one of the harder softwoods, but overall it only has medium hardness and resilience. However, this is usually sufficient for decking. The material is easy to process, although pre-drilling is recommended to prevent cracks.

The material should also be protected to prevent insect or fungal infestation and to extend the service life. In addition, the attractive grain of the wood can be emphasized using appropriate means.

Robinie

Robinia is one of the hard, resilient, durable woods. The material has a striking grain, is comparatively easy to work with and is also resistant to moisture. However, protection against harmful influences with varnish or glaze is still useful in order to increase the service life even further.

Due to the hardness, it is again recommended to make pilot holes when installing the decking boards.

Plastic for decking

Terrace boards made of plastic or solid plastic are generally not offered because the material quickly becomes brittle and rough due to the effects of the weather. In addition, it often does not have the required breaking strength.

Note:

When people talk about plastic decking, they usually mean WPC decking.

WPC decking

WPC is a so-called composite material that consists of wood and plastic. It therefore represents a combination of the materials already mentioned and their properties. The main advantages of this composite material are that it is very easy to care for and moisture-resistant. In contrast to types of wood, it does not require any special or repeated sealing, such as varnish or glaze.

In addition, the material can be shaped much more freely than wood and is also splinter-free. Compared to plastic, the material is more rigid and expands less due to temperature fluctuations. The disadvantages, however, are that the composite material absorbs more moisture than solid plastic due to the wood content and is also less break-resistant than wood. A typical grain is usually missing, so there can be optical deductions.