- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

With well-founded construction instructions and manual dexterity, the high terrace becomes a successful project. The sophisticated construction compensates for uneven terrain in front of the patio door and invites you to relax and sunbathe. With a height of a few centimeters to 1.50 meters, the sun deck is ideal for self-assembly according to your own design or with a kit. This guide will inform you about the materials required, expected costs and optional time expenditure.

Budget-friendly: Build according to your own plans

In contrast to a conventional, paved terrace, the high terrace is a few centimeters to 1.50 meters above the ground. The material of choice is usually weather-resistant types of wood, such as pressure-impregnated spruce, Douglas fir, Siberian larch or WPC wood (wood-plastic composite), instead of heavyweight, expensive natural stone panels.

Landlords with basic knowledge of planning and construction also curb costs and create the outdoor space themselves. If you can forego the use of craftsmen and the purchase of ready-made kits, the dream of your own sun deck is within reach, even for those on a tight budget. The construction principle is very simple and can be modified to any desired size. For your orientation, we present the professional procedure in brief and with in-depth explanations below:

- Stel substructure made of squared timber in the concrete foundation

- Attach beam wreath

- Assembling the patio floor

- Install parapet with privacy screen

- Painting against weather influences

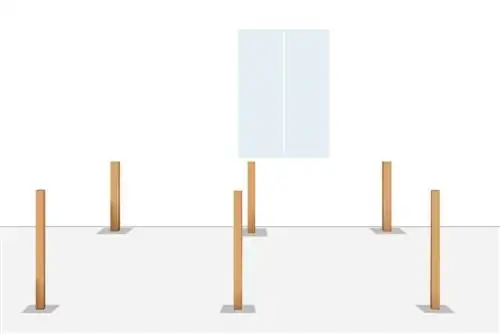

Stel substructure made of squared timber in the concrete foundation

Wooden terraces are based on a substructure made of vertical beams, which are known as stilts or uprights. The number of stilts required depends on how wide and deep the terrace should be. The height of the uprights can be different if the terrace also has the task of leveling out uneven terrain. The stilts are attached to U-profiles made of steel. These in turn are firmly anchored in a concrete foundation. Each post is inserted into a U-beam, aligned precisely and screwed twice for safety reasons. Stilts adjacent to a house wall should also be anchored to it to optimize stability.

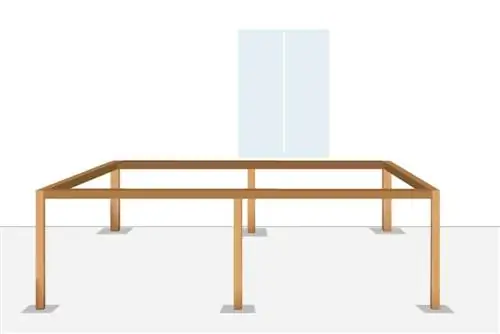

Attach beam wreath

Once the concrete foundation has dried, continue the construction work by connecting the stilts. There are various options to choose from for this purpose. The classic construction instructions usually recommend using a mortise and tenon connection. Alternatively, you can screw the beams together and secure them with angle pieces. Even if it increases the time required, prudent builders opt for diagonal bracing as a supplementary stabilization measure.

Assembling the patio floor

In the next step, the focus is on the upper beam ring. Some cross beams are now screwed onto this as a substructure for the terrace floor. As a rule, homeowners opt for a floor made of wooden planks that are attached to the crossbeams. Popular alternatives are wooden tiles. Fall protection tiles are very popular in family households. A floor covering made of artificial turf is individual and at the same time inexpensive. Which material you prefer as floor covering has a significant influence on the overall costs. While there is little scope for the materials for the substructure, beam ring and parapet, the costs at this point vary significantly. A 20 square meter area made of conventional Douglas fir wooden floorboards costs 460 euros. The price for WPC full profile planks is a whopping 1,620 euros for 20 square meters.

Install parapet with privacy screen

The new high terrace is only complete with a decorative parapet made of squared timber. The railing is attached to the wooden structure and equipped with a matching handrail. To connect the parapet timbers, screw flat boards together as privacy screens. If you like to provide a hospitable view of the sun deck, choose a parapet made of aluminum bars.

Painting against weather influences

Last but not least, the wooden structure is protected against the effects of the weather with a coat of paint. Environmentally and he alth-conscious builders choose an ecologically harmless product, which can be recognized by the “Blue Angel” environmental label. This rough overview demonstrates that building on your own is possible based on basic technical knowledge. Purchasing the necessary materials from the nearest hardware store is beneficial in several ways. The prices are significantly cheaper than in local retailers. Large hardware store chains have the right machines on site for millimeter-precise cutting. As a rule, this service is free. Furthermore, hardware store customers have access to suitable trailers or vans that can be rented for little money if they register in good time.

Tip:

Woods have different swelling and shrinking behavior. Therefore, when building a raised terrace, always use the same types of wood for the substructure and flooring. At first glance, this may seem to increase costs. In the long term, you can effectively prevent annoying stretch damage caused by cracks and dents.

Prefabricated kit saves your nerves and your wallet

A prefab kit from a specialist company saves you the effort of detailed planning work and purchasing materials. Your contribution to the preparatory work is limited to measuring and creating the concrete foundation. The kit comes to your home by freight, ready for assembly. Detailed construction instructions are included in the price. Competent providers are also available to provide advice and support over the phone and, if necessary, can arrange for a local craftsman if doing the assembly yourself is too much for your skills. So much luxury has its price. In order to demonstrate the cost level, we have created the following representative offer:

- Dimensions: 300 cm length x 220 cm depth x 100 cm height

- 4 support supports

- 4 straps

- railing with slat filling made of Douglas fir

- Douglas fir patio flooring

- Price without stairs and transport costs: 6,820 euros

In order to illustrate the wide range of costs, the following offer presents you with an elegant model version that is half the height and has a spiral staircase, WPC floorboards and integrated lighting:

- Dimensions: 300 cm length x 220 cm depth x 50 cm height

- 2 support supports

- 2 straps

- railing with batten filling made of WPC wood

- Patio flooring made of WPC wood

- 5 integrated floor lights

- Price without transport costs: 10,385 euros

Time expenditure forecast

How much time needs to be calculated for the construction work depends on a variety of factors. If you dedicate yourself to detailed planning work, including measurements and calculation of the cost of materials, you will be busy for a weekend. Another weekend should be reserved for purchasing the necessary materials. You can estimate around 14 days for the construction work, provided you sacrifice your vacation for the project and one or two helpers are available. Choosing a prefabricated kit shortens the time required by around half. This forecast is based on the premise that you can draw on a sufficient we alth of experience in manual work.

Observe building regulations and neighborhood laws

Before you start building your new high terrace, please consult the regional building regulations. In many federal states, a building permit is required for heights of more than 50 centimeters because the terrace is considered a self-supporting structure. According to neighborhood law, the consent of the neighbor is required in many federal states and municipalities if the terrace area is less than the minimum distance of 250 centimeters to the neighboring property. The requirement also applies if the neighboring property is not built on.