- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

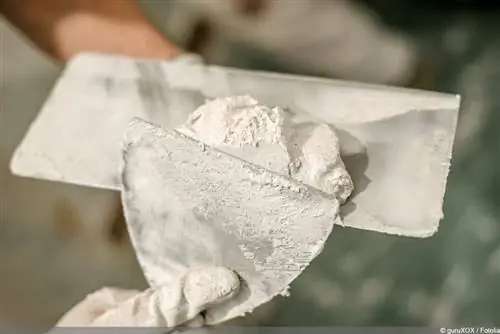

Felt plaster is not a special type of plaster, but a special type of processing. It is used when plastered surfaces need to be very smooth. However, in order to achieve this result, some factors must be taken into account. A lot of knowledge and sensitivity are required, from choosing the plaster to adding the surcharge to timing it correctly.

Plastering

The felt method for smoothing the plaster is best suited to lime mortar that has been enriched with a fine sand aggregate. The sand should have been sifted beforehand to create a particularly smooth surface. The lime mortar is applied two to four millimeters thick and only then worked on with a felt board.

Preparation

The plaster should only be applied once a surface has been prepared with an appropriate primer. The primer must also be completely dry before the lime mortar can be applied and smoothed with a spatula. It is also important that the plaster has already dried slightly. If it is still too moist, smoothing cannot be carried out successfully. The same applies if the plaster has already dried too much. Inside, this state is usually achieved within a few hours. Outside, the drying time depends heavily on the current temperature and weather.

Area size

Felt plaster is particularly suitable for smaller areas or areas that are divided into smaller sections. Cracks can form on larger areas and become very visible very quickly. The reason for this can be found in the processing. By rubbing with the felt board, the binding material compacts on the surface. This leads to tensions. These mainly occur when the lower layers are still comparatively moist and therefore push outwards to dry out. The already dried outer layer is exposed to tension and can tear.

The larger the area, the higher the risk of tension and therefore cracks.

felt board

A so-called felt board is required to make felt plaster. This is a board made of wood or plastic that has a handle and a felt coating on one side. Either the felt layer itself or the plaster can be moistened to work on and smooth the surface.

Apply and use felt plaster - step by step

In theory, the application or processing of felt cleaning is comparatively easy. All you need is the following steps:

- A primer is applied to the surface to be plastered. If necessary, it may be necessary to level out cracks, holes and gaps beforehand.

- The primer should be allowed to dry completely. Depending on whether the felt plaster is to be applied indoors or outdoors, drying can take a few hours or several days. Of course, the current weather, humidity and temperature also play a role.

- After the primer has dried, the plaster can be applied. It should be two to four millimeters thick. It is also important to distribute and process the plaster as smoothly and evenly as possible.

- The plaster should dry enough that it can still be worked on but has already dried well. When you test pressure with your hand, it still feels slightly cool and moist, it gives in to pressure, but does not deform immediately with every small force applied.

- For processing, either the felt board or the felt layer or the plaster itself are moistened.

- To create a smooth surface, either the felt board or the plastered surface is moistened. The felt board is used to rub the plaster over the plaster in circular movements with light pressure.

Tip:

Plastering strips help to plaster the wall and divide it into smaller sections.

Do it yourself or hire a professional?

As easy as processing felt plaster sounds, a smooth result depends on the right timing, experience and sufficient sensitivity. It therefore usually makes sense to leave the work to a specialist. Especially if you have never plastered before, felt cleaning can be a real challenge. In addition, the respective risks should be taken into account. These include:

Cracks and weak points

Due to the high risk of cracks, especially on larger surfaces, weak points on walls and ceilings quickly arise. The plaster can partially break off and holes can appear.

Short lifespan

Due to the weak points, the service life of the plaster is shortened. This is at least true if it was not applied properly.

Uneven distribution

Rubbing can cause uneven distribution and compaction. Aside from the risk of cracks, this also creates problems with the distribution of heat, moisture and overall insulation of walls and ceilings.

If you have no experience or knowledge in plastering, you should therefore have it plastered - instead of plastering yourself.