- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

The heating system's expansion tank regulates the pressure in the system and is therefore crucial for efficient heating performance and function. Regular maintenance of the pressure compensation tank can prevent problems.

Expansion vessel - task

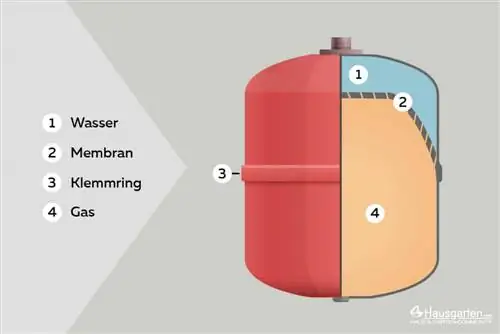

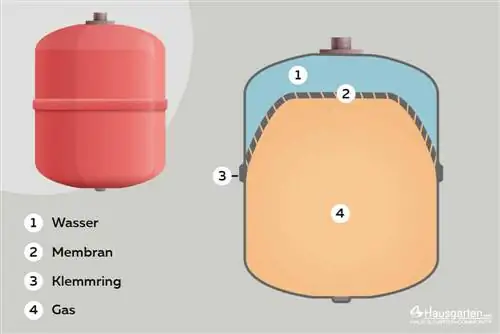

The pressure compensation tank consists of a chamber for water, a chamber for gas and a membrane located in between. When the water in the heating system is heated, its volume increases. This allows more water to enter the expansion tank chamber and the membrane compresses the section that contains gas.

If the water cools down and the volume is thereby reduced, the pressure of the gas causes the membrane to move in the other direction and the water is flushed back into the heating system. This equalizes the pressure differences and enables efficient heating.

Common Error

If the heating stays cold or only heats up unevenly, you often just need to top up the water. This also applies if water drips from the safety valve. The problem here is that water is constantly being refilled, but this can result in the level being too high. As a result, water is constantly lost.

In addition, the actual cause can be misunderstood. A leaky valve, a crack in the membrane, too little gas or pressure are possible triggers. These, in turn, cannot be remedied by the water level alone. When carrying out a check, various factors should therefore be taken into account.

The correct pressure in all areas is important for the functioning of the heating system. Therefore, the pressure should be checked urgently during an inspection. If this is too high or too low, regulation must take place.

How high the pressure should be depends on the respective system and the amount of heating water. Apps, programs or computers from expansion tank providers can be used as orientation.

Valve and membrane

The safety valve is used to prevent overpressure. If the pressure rises too high or is set too high, water escapes and has to be refilled again and again. The valve can be checked by:

The pen is pressed in slightly

If water and not just gas escapes, a crack in the membrane is very likely. In this case, the pressure compensation tank must be replaced because the membrane alone cannot be replaced.

Checking with a cloth or bucket

Wiping with a cloth is an easy way to determine whether the valve is sufficiently tight. If the cloth gets wet, either the pressure is too high, there is too much water in the system or the membrane is torn.

Pressure is applied

A light pressure test on the valve pin can be used to determine whether it can be moved easily or whether it stalls.

Water

If the filling level of the heating system keeps decreasing and water has to be refilled very frequently, there may be various reasons for this. Including damage to the valve and membrane.

In any case, it is crucial to check the water level during maintenance. This means that this point must be on the checklist.

Gas

The second chamber in the expansion tank is filled with gas. Theoretically, it can be filled with ordinary air using an air pump. However, it is better to use nitrogen. This does not cause any corrosion and therefore protects the entire system, even if the membrane breaks and the gas gets into the heating system.

When checking, make sure that there is sufficient pressure but not too high. If necessary, the chamber must be refilled with gas.

Knock

The easiest way to check is to tap the expansion tank. In the gas area it should sound completely hollow. In the area of the water chamber, the sound should become duller when tapping. By tapping it, you can quickly and easily determine whether the membrane is still intact or whether there has been a crack and thus mixing of water and gas.

Ideally, this check should be done at the time of purchase in order to get a feel for the right sound. The instructions from the installer can also be helpful in determining whether there are any problems using this simple test alone.

Frequency

Many people make the mistake of only carrying out a check when problems such as uneven or insufficient heating, leaking water or noises already occur.

It is better to carry out preventative checks every one to two weeks so that damage and possible problems can be identified and corrected at an early stage. This saves time and effort.