- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

Calculating the size of the expansion tank for heaters is crucial for efficient heating. If it is too large, sufficient pressure cannot build up. If it is too small, overpressure occurs.

Factors

Selecting the right pressure compensation tank is crucial for the functioning of the heating system. Efficient heating and the avoidance of problems and damage is only possible if the expansion vessel is correctly matched to the system.

Various factors must be taken into account:

- Expansion volume

- required water template

- Filling pressure of the heating system

- Nominal volume of the expansion tank

- Pre- and final printing

- Water content of the heater

Note:

Different conditions and calculations must be taken into account for each factor.

Expansion volume

The expansion volume plays an important role in selecting the correct expansion vessel and must also be calculated. Two factors are important here. On the one hand, the so-called system volume, i.e. the amount of water in the heating system. On the other hand, the flow temperature.

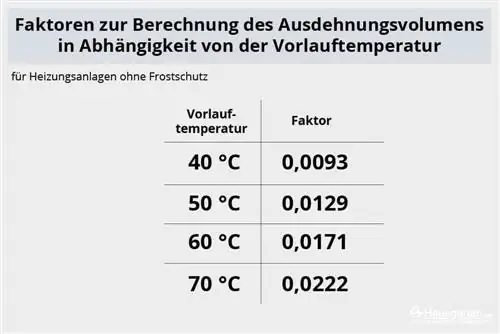

Because these factors determine how much the water volume can change or increase when heated. Depending on this, the system volume is multiplied by another factor. This is a factor that depends on the flow temperature. The following factors apply to heating systems without frost protection:

- 0.0093 at 40 °C

- 0, 0129 at 50 °C

- 0, 0171 at 60 °C

- 0, 0222 at 70 °C

However, it must be noted that the values can differ depending on the type of heating system. You should pay attention to the manufacturer's information or ask the provider if necessary.

A heater with a system volume of 200 liters that runs at a flow temperature of 70 °C can serve as aExample calculation.

200 liters x 0.0222=4.44 liters expansion volume

The expansion tank should therefore have at least this capacity. If a vessel of the appropriate size is not available for the heating system, a pressure expansion tank of the next larger capacity should be used.

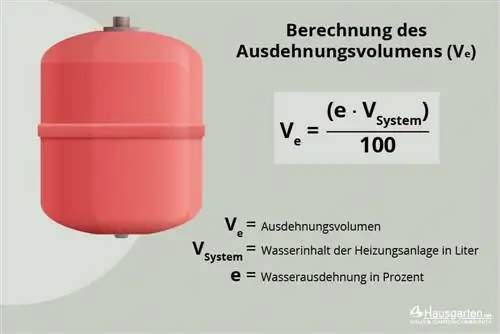

If you want to calculate the expansion volume (Ve) for other temperatures, you can use the following formula and table as a guide:

TheExample with a system of 200 liters and a temperature of 120 °C can illustrate how the calculation is done:

- Ve=(e x VSystem): 100

- Ve=(5.93 percent x 200 liters): 100

- Ve=(1.186): 100

- Ve=11, 86

Required water template

The water reserve is to be understood as a reserve that can bridge the gap between maintenance intervals. Regardless of the system volume, at least three liters should be planned as a water reserve.

For larger systems, 0.5 percent of the volume should be kept ready and included in the calculation. For a heating system with 200 liters, 0.5 percent would only be 1000 milliliters. Three liters should still be filled and planned to compensate for the normal losses.

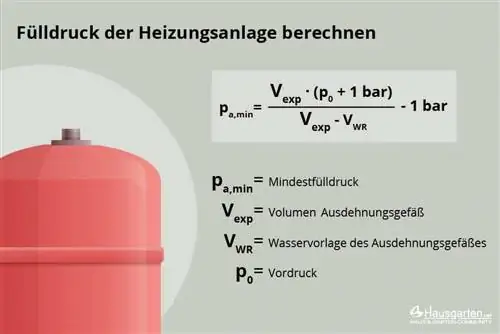

Filling pressure of the heating system

In order to find the right expansion tank for the heating system, the filling pressure must also be known. To calculate this it is first necessary to use this formula:

As a result, the heating is filled up until the minimum filling pressure is reached.

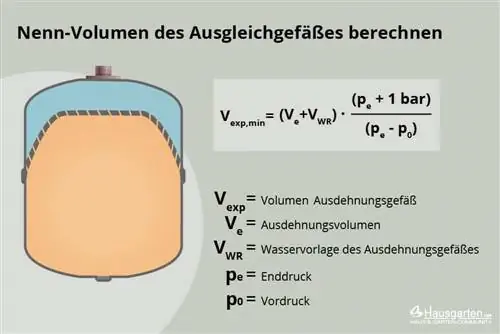

Nominal volume of the expansion tank

The expansion tank requires an appropriate volume to be able to absorb the necessary amount of water. The volume can be calculated using the following formula:

Pre- and final printing

Once the expansion volume has been calculated, the pre-pressure and final pressure can also be determined. The pre-pressure should be at least 0.7 bar. To calculate it, the altitude pressure is added to the vapor pressure.

The altitude pressure results from the system height, which is divided by ten. With a distance of five meters between the expansion tank and the system, the following calculation results:

5 m: 10=0.5 bar

The flow temperature must be taken into account when determining the steam pressure:

- 0, 2 bar at 60 °C

- 0, 3 bar at 70 °C

- 0, 5 bar at 80 °C

This value is now also added to get the form. In our example calculation for a system with a flow temperature of 80 °C this means:

- 5 m: 10=0.5 bar

- 0.5 bar + 0.5 bar=1.0 bar

The final pressure can be easily determined from what response pressure the safety valve has and should be 0.5 bar below this limit. With a response pressure of 3 bar, the final pressure should be 2.5 bar.

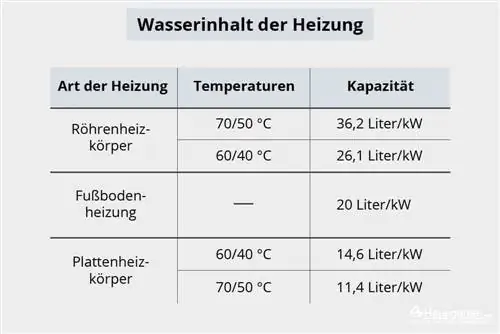

Water content of the heater

How much water is in the heater determines how large the pressure compensation tank must be. However, the capacity depends not only on the sheer amount of water, but also on the temperatures and type of heating.

- 36, 2 liters per kilowatt for tubular radiators at 70/50 °C

- 26, 1 liter per kilowatt for tubular radiators at 60/40 °C

- 20 liters per kilowatt for underfloor heating

- 14, 6 liters per kilowatt for panel radiators at 60/40 °C

- 11, 4 liters per kilowatt for panel radiators 70/50 °C

The so-called system volume is achieved by multiplying the characteristic values and the performance of the heating system. For heating systems with a particularly large buffer storage, this buffer must also be taken into account. It is added to the result to take the total water volume into account.