- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

The expansion tank of the heating system fulfills important tasks. If it is defective, several problems can arise. Regular maintenance and repairs can prevent difficulties with the expansion tank and thus with heating.

Expansion vessel - function

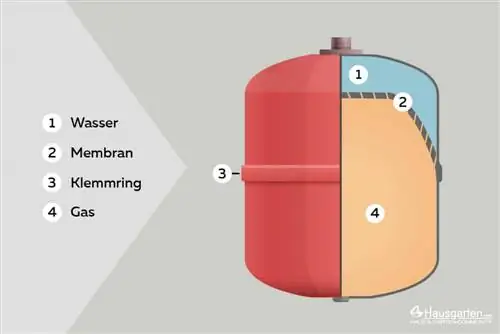

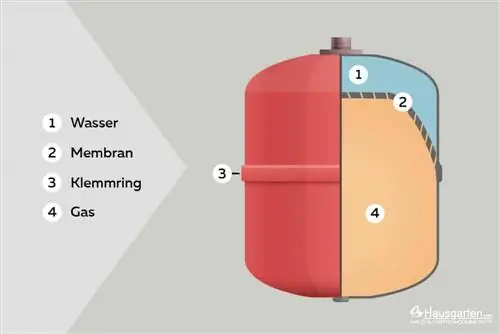

The expansion vessel consists of a chamber that is divided into two areas by a membrane. Water is filled in one area that can be fed to the heating system. The other has gas in it. This is usually nitrogen, as this can prevent corrosion.

When water is heated, its volume increases. This causes the membrane to move. The gas is compressed. If the temperature decreases again, the volume of the water also decreases. The membrane moves back and the gas has more space to expand again. This also allows water to flow back into the heating circuit. However, this is not possible in the event of defects or other problems.

Signs

Signs of a defective expansion tank or difficulties in the pressure compensation tank include:

- “gurgling” noises

- water leaking from the safety valve

- significant pressure fluctuations during heating

- lack of heating power, only slight warming

- cold or unevenly warm radiators

Membrane rupture

A tear in the membrane between the chambers filled with water and gas is particularly problematic. In this case, the two substances can mix and the heating output drops significantly while the pressure fluctuates greatly.

Changing the membrane is not possible. Instead, the entire expansion tank must be replaced. An installer should be called in for this. However, the container can also be replaced yourself if the correct procedure is followed.

Wrong size

If the wrong size was selected for the pressure compensation tank, the pressure cannot be compensated accordingly. In order to calculate the correct size, the design of the heating system must be taken into account. The following factors are also crucial:

- Amount of heating water

- Operating temperature

- response pressure

A corresponding vessel can be purchased very cheaply. The prices range between around 30 and 100 euros.

Incorrect print

The working range of the pressure compensation tank must be adjusted correctly. Otherwise problems may arise. For the working area, it should be taken into account that it is at least 0.3 bar above the minimum pressure. Otherwise, negative pressure can occur, which can have a negative effect on the entire system.

Tip:

Apps or PC programs can help when calculating and setting the correct pressure for the work area, which are usually offered directly by the manufacturers and are designed for the respective heating system and the pressure compensation tank.

If the operating pressure is too high, water will escape from the safety valve. In addition to the dripping valve, a clear sign of this is that there are high heating water losses and the system has to be refilled again and again.

Another problem in the area of pressure can be the minimum pressure already mentioned. This results in:

- Sounds

- Decreased performance

- Boiler shutdown

Just as with an incorrectly set pre-pressure, the container can also fill up, meaning that there is not enough space if heated heating water has to be absorbed with a larger volume.

Leaking valve

The safety valve is used to prevent overpressure if necessary and to drain water for this purpose. To do this, once a certain pressure is reached, the valve is opened and pressure is released.

However, if the valve is leaking, water will escape at a significantly lower pressure and no corresponding operating pressure can be built up.

False gas

If there is oxygen in the gas section, this can lead to corrosion of the metal in the event of a leak. This in turn creates weak points and defects that can result in costly repairs and the purchase of replacement parts. The gas container should therefore always be filled with nitrogen.