- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

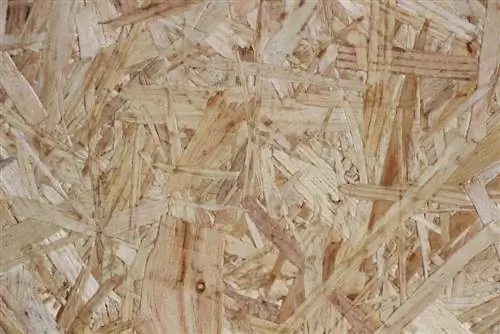

OSB boards are still a relatively new building material in Europe, which is why questions always arise about both their use and finishing. In principle, it is easily possible to paint, varnish or even wallpaper the chipboard. However, due to the special nature of the plates, some factors must be taken into account.

Paint

Ordinary wall paint is sufficient for painting. Again, the panels should be sanded and ideally untreated. The only exception is pre-treatment with a blocking reason. If you choose unsanded panels, you must sand and vacuum the surface before painting. Only then is there a correspondingly smooth surface and both the risk of injury and the risk of chips tearing out and breaking off are reduced.

Tip:

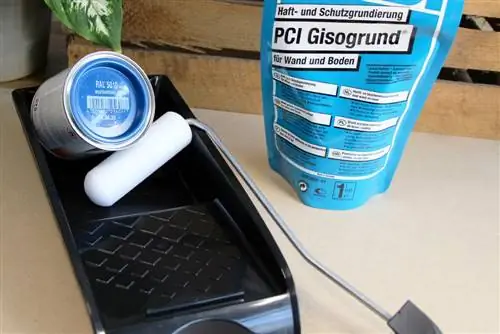

A barrier primer applied before painting prevents the paint from absorbing or covering unevenly and also prevents the coarse chipboard from warping and swelling.

Painting

When painting the OSB panels, the procedure is the same as when painting. The panels should be sanded and treated with barrier primer. Only then can the paint be applied in such a way that an even result can be achieved. It is also important that a solvent-based paint is chosen if possible. With water-based paints, the edges of the panels can lift as there is a risk of swelling. Whether the structure of the Oriented Strand Boards - as the boards are also called - is still visible or not, of course, also depends on the paint chosen. Opaque, colored variants make the pattern disappear. Light tones and transparent varnishes allow them to shine through.

glazing and staining

Using glaze and stain allows you to preserve the structure of the panel surface while making the material more durable and resilient. However, this type of finishing is not suitable for heavily used and heavily used surfaces. It is better to apply another layer of transparent varnish after applying the stain or glaze. This makes the result more durable and moisture or sunlight does not cause fading or discoloration in a short time.

Wallpapering

Manufacturers of OSB boards advise against wallpapering them. The simple reason for this is that the panels expand according to the prevailing humidity and then contract again when they dry. When the wallpaper paste dries, the wallpaper could crack. Nevertheless, it is possible to refine the coarse chipboard in this way. It is necessary to pay attention to the following points:

- Choose water vapor permeable wallpapers

- Use paste that is suitable for the OSB board

- Sand the surface to achieve an absolutely flat and smooth result

An alternative is waterproof fiberglass wallpaper, which is applied to the panels or wall with dispersion adhesive. When doing this, it must be ensured that there is no air between the wallpaper and the surface. This creates a seal on the wood, which can also prevent it from swelling.

Oil and waxing

The coarse chipboards can be oiled or waxed without any problem. However, these methods only make sense if the plates are only subjected to little stress. For example, in the ceiling area or on walls that are in rarely used rooms. One advantage of oiling and waxing is that light scratches can be leveled out quickly and easily. In addition, the visually appealing structure is retained.

Tip:

There is very little that needs to be taken into account when oiling and waxing the OSB boards. The products should be of high quality and the panels should be sanded and untreated. Then the best results can be achieved.

Prepare OSB panels

Depending on which finishing variant is chosen, the panels must be prepared accordingly. As mentioned, this primarily involves grinding. This is important in order to make the surface absorbent and smooth it. Only then should the barrier primer, paints, varnishes; Oils, waxes or stains are used. Of course, this is not necessary for variants that have already been treated. Sanding is also useful because chipping and uneven edges not only affect the appearance but also pose a risk of injury. This is only a minor problem on the ceiling. On walls and floors as well as surfaces used for other purposes, splinters and chippings are risky.

Perform refinement

It is important for any type of finishing - with the exception of wallpaper - that several layers are applied. Because the panels are absorbent, a layer of varnish or paint alone cannot achieve an opaque and even result. The timing of the refinement is also crucial. The following steps should be followed:

- After preparation by sanding and attaching the panels, they should be able to adapt to the room climate for at least 48 hours. Spacers may need to be used to prevent warping and shifting. However, depending on whether the room is damper or drier than the previous storage location, the panels will still contract or swell.

- After acclimatization of two days or more, assembly can take place.

- Once installation has been completed, finishing can begin and the barrier or insulation base can be applied. It is important that all further finishing steps are completed within 36 hours if possible. Otherwise the plates can warp, bend or move against each other.

- Varnishes, paint or oil should, as mentioned, be applied in several layers in order to achieve the highest quality and most resistant result possible.

Utensils

In order to achieve appropriate refinement, the right utensils must be used in addition to high-quality products.

Depending on the type of finishing, the following utensils are:

- Brush: Oil, wax but also stains and glazes can be easily applied with brushes. These are also ideal for finishing edges and joints.

- Paint or varnish roller: Paint rollers are ideal for larger areas and for applying paint and varnish. They are particularly suitable for applying the products very evenly.

- Cloth: Applying or wiping with a cloth is only recommended for oils and waxes. Even then, wide brushes are usually the better choice

In any case, the products should be stirred thoroughly before application and gloves should be worn.