- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

Plaster is usually applied to the walls of a house. Window plaster is also considered one of the most commonly used when an external wall needs to be cleaned. The structure can be changed again and again if desired; this is achieved by applying, processing and structuring correctly. How to proceed with the various work steps is explained in the following article.

Window cleaning - definition

Window plaster, also known as rubbing plaster, is a granular to coarse-grained material based on synthetic resin or minerals. Synthetic resin plaster is easier to process and is available in stores ready for use. The plaster made of synthetic resin can also bridge cracks in the wall. Mineral plasters, on the other hand, are usually applied indoors as they offer a natural indoor climate.

Materials and equipment

Before starting work, the required materials and equipment should be provided. This ensures, above all, quick and effective work. The color should also be chosen before plastering the wall. A plaster tinting paint is required for this. The desired color can be selected on color cards, which is then mixed into the plaster used at the same time in the correct mixing ratio as explained on the packaging. Otherwise, the following equipment and materials are required for application:

- Rubbing plaster, tinted or not

- Primer paint for plaster

- trowel for application

- Stainless steel trowel to remove the plaster

- floater

- Whisk and drill

- Adhesive tape and masking film

- Filler to level out any holes beforehand

- Deep primer to prepare the wall

- tassel or paint roller

Depending on how high the house wall is, a mobile scaffolding should be set up. These are also available for rent from specialist retailers. Since the mobile scaffolds are on wheels, they can be pushed back and forth along the wall. A ladder is sufficient for low heights. However, the mobile scaffolding is also more stable overall than ladders.

Tip:

Covering film with directly attached adhesive tape is often available in stores. If this is used, the often annoying and time-consuming process of covering can be done more quickly.

Step-by-step instructions

When applying and structuring the window plaster, various steps are now carried out. It should be noted that the wall must definitely be prepared before application.

Prepare exterior wall

First of all, all surfaces and the floor that do not receive plaster must be masked off. This is important because when applying it with a trowel, particles could fall off the plaster and then stick to the floor or a window frame. Covering it avoids the hassle of later cleaning. The wall to be processed is then further prepared as follows:

- Detecting unevenness on the wall

- level this out with filler

- apply with a spatula and smooth it out

- Let it dry thoroughly before applying plaster

- there are highly absorbent masonry structures

- these must be provided with a deep primer

- this is applied to the entire surface with a roller or tassel

- let it dry thoroughly

If the wall has been prepared accordingly, a plaster primer can also be used. This is also distributed over the entire area with a paint roller. A small brush should be used for the corners and edges. Painting with the primer paint gives the wall an even white color. This paint must also dry thoroughly before applying the plaster.

Tip:

Especially with an exterior wall that is primarily exposed to street dust, it is important to clean it thoroughly before starting work. Above all, everything should be free of grease and dust, otherwise the window cleaning will not hold.

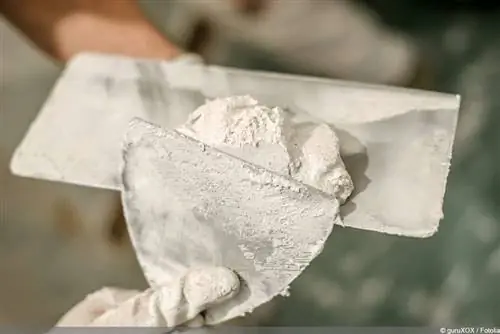

Mix window cleaning

The window cleaning is usually available commercially as a powder and must therefore be mixed with water. This is where the drill with the whisk attachment comes into use. Ideally, not too much plaster is mixed, so that the inexperienced do-it-yourselfer can get an estimate of how much plaster he can process in 15 minutes. Because window plaster dries quickly and can no longer be used. When mixing window plaster, you should pay attention to the following:

- stir in color if desired

- Always pay attention to the manufacturer's instructions

- The ratio of plaster to water is stated on the packaging

- this should be strictly adhered to

- If the plaster is too liquid or too thick, it won't stick to the wall

- too liquid plaster running down

- plaster that is too thick simply falls off

- Ideally mix in an old, clean paint bucket

- Circumference so large that the plaster can be easily removed with a trowel

Tip:

Most manufacturers recommend letting the window cleaning rest for a certain time after mixing and then stirring it again. This information should always be taken into account and fulfilled so that the plaster adheres well to the wall.

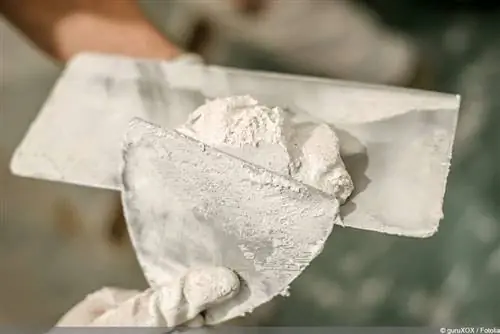

Apply window plaster

The next step is to apply the window plaster to the wall. If you've never done this before, you should practice a little in a hidden corner. A little plaster is removed from the bucket with the trowel and spread onto the stainless steel trowel. With this the plaster is now placed on the wall. Please pay attention to the following:

- Fill the ladle only halfway

- then transfer to the smoother

- makes it easier to apply the plaster to the wall

- Pull the plaster generously over the wall

- smooth the applied surface

- To do this, keep the straightener steep

- A lot of care needs to be taken here

- the plaster must have a uniform layer thickness

If the plaster has tightened a little, which can be seen by the fact that it is no longer shiny, then you can start structuring.

Tip:

In order to have an indication of how thick the layer of plaster on the wall can be, you should pay attention to the grain thickness. The grains contained in the plaster should therefore only show a single layer and should not be placed on top of each other.

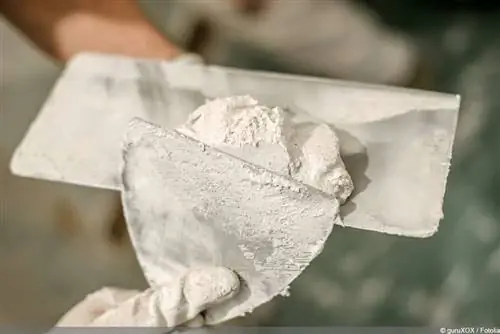

Structuring

The plastic float or a so-called trowel is used for structuring. The desired structure should be carefully considered beforehand. Here too, it is helpful to practice a little in a corner that is not easily visible if plastering and structuring have never been carried out before. In such a case, if you start in the middle of the wall and don't get it right, then this is very annoying. The structuring procedure is as follows:

- texturize within 15 minutes of application

- otherwise the plaster surface has already dried too much

- can no longer be structured

- Use a float to draw the desired structure into the damp plaster

- circular

- diagonal

- horizontal

- crosswise

In this way, layer by layer is applied to the wall until an even structure is created, where care must also be taken to avoid transitions.

Tip:

If an area has been completed where plastering was carried out over the adhesive strip of the cover, the adhesive tape must be removed as long as the window plaster has not yet completely hardened. Otherwise the tape will dry out and can either no longer be removed or the plaster will crumble at this point.

Why structure?

The question could be asked why the applied plaster still needs to be structured or even scraped off. But that is simply explained. Structuring removes the color from the grains in the plaster. This gives the plaster a special surface. A plastic float or trowel is used for the work. Many do-it-yourselfers also use a sponge board for this. This has the following properties:

- This highlights the grain structure more

- the plaster seems coarser

- To do this, make circular movements with the sponge board

- until grains are exposed

Tip:

If a larger area of a wall is to be plastered, it always makes sense to work with at least two people. This means that one person can apply the plaster to the wall and the second can structure it directly. This means work goes faster without waiting times. Visible transitions can also be easily avoided.