- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

If you have a wooden floor, you should coat it with hard wax oil. This makes the wood resistant and robust, it is preserved and protected. It is therefore particularly suitable for particularly stressed floors, for example in a room with children playing. But all other wooden furniture can also be upgraded with the oil. Any DIY enthusiast can do the processing, polishing and application themselves.

The right wood

Not all types of wood or furniture are suitable for being coated with hard wax oil. So it is not so suitable for dining tables or kitchen worktops. Hot dishes can form a white halo on a plate treated with hard wax oil. Otherwise the oil can be used as follows:

- Open-pored wood is well suited

- here 35 to 50 cl are needed for one square meter

- also suitable for end grain, balsa, fired brick or cork

- highly absorbent surfaces

- need more oil

Tip:

Hard wax oil darkens a little after it has hardened. In this way, the contrast in the wood is enhanced and a visually appealing grain effect is achieved on previously very light wood.

Tools required

Since the processing has to be carried out in several steps, various tools and accessories are also required. This should be put together before work begins so that there are no unnecessary breaks. In addition to the sufficiently calculated doses of hard wax oil, the tools and accessories also include:

- Gloves that should be used during application

- a sander for a large area

- If only a small piece of wooden furniture is oiled, sandpaper is sufficient

- Face mask that should be used during grinding work

- Vacuum cleaner with brush attachment

- Feud and bucket for wet cleaning

- clean brush for dusting in corners

- wide brush or small roller for applying the oil

- Cotton cloth for polishing small areas

- Plate machine for large-area polishing

Tip:

If you don't own a sander or a disc machine and don't want to buy one, you can rent these devices for a day or longer from a hardware store for a small rent.

Preparing the wood

Before processing and applying the hard wax oil, the wooden surface to be treated must be prepared. To ensure that the oil is well absorbed later, the wood must be thoroughly cleaned and sanded beforehand. If you have a parquet floor, first vacuum it, then wipe it with a damp cloth and let it dry thoroughly. Only then does the sanding begin. For this purpose, a sanding machine should be used, especially for large areas, as it works more evenly than when working by hand and sandpaper. The preparation then continues as follows:

- After rough sanding, vacuum and wipe again

- let dry

- fine grinding

- vacuum again and wipe, let dry

- stain the floor or wooden furniture before applying the oil

If the floor is not cleaned thoroughly before sanding and between sanding processes, then dirt residue during sanding can leave deep grooves and scratches in the wood. It is irrelevant whether an old floor is to be refinished or a new floor has been laid.

Tip:

If the wood is stained after sanding and before applying the hard wax oil, it will later absorb the oil better.

Further preparation

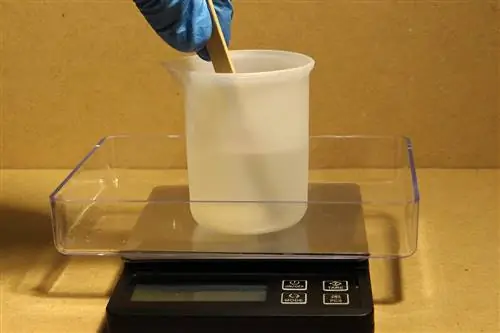

Once the wood has been prepared, the hard wax oil can be processed. This is usually delivered ready for use and therefore must not be diluted. When working, use a clean, small brush for the corners and edges, as well as a clean, wide brush for the surfaces. A small roller can also be used for the surfaces. Then proceed as follows:

- Shake container with oil well before use

- use only in a well-ventilated room

- Plants, animals and children should not be around

- Humidity in the room not above 85%

- Room temperature should be between 12° Celsius and 25° Celsius

Tip:

Even if there is an aquarium in the room where the parquet is to be renewed, it should be removed from the room before working with the hard wax oil.

Apply

If all necessary measures have been taken, the oil can be applied. When working, it is recommended to wear gloves for your own protection. A face mask is also helpful so that toxic fumes are not inhaled. With a parquet floor, start in the farthest corner from the door. For a piece of furniture, start with the corners and edges. The procedure is as follows:

- apply the oil in an even covering layer

- always work in the direction of the wood

- Always spread out long with a brush or roller

- don't make short brush strokes

- Usually two steps are necessary

- wait about 8 - 10 hours before applying the second coat

- a third layer may also be necessary

- that's because of the wood

- However, the drying time between two coats must not exceed 18 hours

Tip:

A sealant cannot be applied to parquet treated with hard wax oil. However, to increase the protection of the floor, a third, colorless layer can be applied after two coats of colored hard wax oil.

Polishing

After each layer of hard wax oil, the processed surface must be polished. For large areas it makes sense to use a plate machine. The pad should be either white or beige. Small surfaces and furniture are polished with a clean, soft cotton cloth. When polishing the wood painted with oil, proceed as follows:

- polish with oil immediately after painting

- polish well and vigorously

- is especially important when working with the cloth

- so the hard wax oil gets into all pores

- This ensures uniformity

- gives a more beautiful look

- then let the wood dry

- ensure sufficient oxygen supply

- Open the window wide in the room

Final curing, especially for parquet floors, is guaranteed after about ten days. A floor can be walked on carefully after just two to three days. The pieces of furniture that have been processed should only be put away and used again after ten days. In the first few days, cleaning should only be done with a broom or vacuum cleaner; damp wiping should be avoided.

Tip:

So that the parquet remains attractive after processing, do not move heavy furniture, but always lift it. Felt gliders can be stuck under chairs and tables. Do not place plant pots directly on the wood but insulate them well.

Cleaning of work equipment

The tools and work equipment should be cleaned well immediately after processing. Use thinner for brushes and rollers. Place this in a container and place the work materials in it. The brushes and rollers must also be stored in the thinner during the break between two work processes. Otherwise the oil dries up and becomes hard and the brushes can no longer be used. You should also pay attention to the following when cleaning:

- Do not dispose of thinner and oil residues down the drain

- put in a closed container

- Dispose of pads and rags used during polishing

- take it to the pollutant yard and hand it in

Renovate small areas

Hard wax oil can also be used on small areas, for example if stains have formed. These can arise from incorrect treatment, for example from a burn mark from a cigarette or a water stain. To do this, proceed as follows:

- Sand the stain locally

- Remove dust with a brush or cloth

- coat the area with hard wax oil

- polish with a soft cotton cloth

- Let dry and repaint

- polish again

Tip:

The local stain should be treated in the same way as the entire cabinet or the entire parquet. So choose the same color here and possibly paint a third layer with a neutral color. For this purpose, it is advisable to keep a remainder of oil after the first, major treatment.

Storing leftovers

If any hard wax oil remains after processing, these can of course be stored and do not have to be disposed of. However, since the oil is flammable, the following procedure should be followed when storing leftovers:

- Close container tightly

- store in a dry, well-ventilated and cool room

- Boiling cellar is not a good choice

- keep away from any risk of ignition and heat sources

- No smoking in the storage room either

- Hard wax oil also protects against frost