- Author admin [email protected].

- Public 2024-01-31 11:14.

- Last modified 2025-06-01 06:48.

Concrete and screed can be found on almost every construction site. Whether just the floor slab or the entire building: the range of uses for the building material is very versatile. Read here how much material the usual container sizes produce and how much is required.

Screed and concrete are usually available in 25 kg and 40 kg bags. The following article explains which container size produces which amount of ready-to-use concrete or screed using simple example calculations.

Screed and concrete - differences and areas of application

The forerunner of today's concrete was used around 10,000 years ago. To this day, now thoroughly developed and mature, it is an indispensable material for construction projects.

Although these are such widely used materials, there is often confusion about what the difference between concrete and screed actually is. Many users are also not aware for which purpose which of these very similar building materials is the right choice.

Concrete

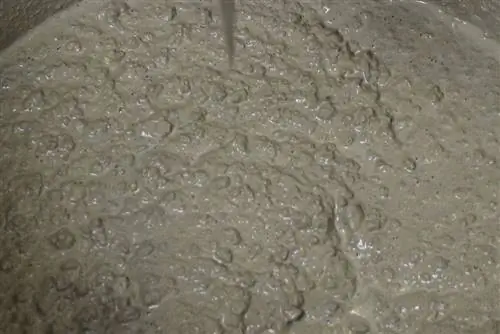

This consists of clay with lime (=cement), gravel or sand, binding agents and catalysts. For special types of concrete, additional ingredients may be added. After adding mixing water, chemical processes come into action that cause this mixture to harden into a crystalline composite. Possible areas of application include foundations, highly resilient components of various types and much more.

Screed

The surface of a concrete foundation is too rough and uneven to lay flooring on. A layer of screed is used here to straighten it. The composition of screed is fundamentally similar to that of concrete. However, the components of the screed can vary depending on the intended use. A significant difference between screed and concrete is that not every type of screed requires water to react.

Concrete screed

A type of screed that has a very similar composition to concrete is called a concrete screed. This screed is the classic straightening layer that is applied to foundations and, like concrete, requires water to harden. Since the sand in the concrete screed is significantly finer-grained than in concrete, you get a smoother surface on which the floor can then be built up.

Calculate required quantity

If the volume of the planned concrete component is known, it is quite easy to determine the required number of bags of the desired concrete dry mix. Of course, it is also possible to build the formwork first, then measure it and calculate the volume on this basis.

How the calculation should be carried out in individual cases is explained below using the example of a small foundation.

Calculate the volume of the component

Volume of a cuboid:

Length [in m] x width [in m] x height [in m]=volume [m³]

Example: 2.2 m x 3.5 m x 0.2 m=1.54 m³ volume to be filled with concrete.

Convert cubic meters to liters: 1 m³ corresponds to 1000 L=>1.54 m³ x 1000 L/m³=1540 L

1540 L of concrete is required.

Tip:

If you want to rule out potential errors due to incorrect entries in the calculator with more complex geometries, you can find easy-to-use online volume calculators using a search engine. Different units can also be converted quickly and easily.

Dry mix for the volume to be poured

Rule of thumb:

1 kg of dry concrete mix makes approximately 0.525 L of mixed concrete.

1540 L / 0.525 L/kg=2933.333 kg dry mix required.

It takes 2933, 333 kg of dry mix to get 1540 L of mixed concrete.

How many bags of concrete are needed

| 25 kg bag | 40 kg bag |

| 2933, 333 kg: 25 kg/bag | 2933, 333 kg: 40 kg/bag |

| =117, 333 bags | =73, 333 bags |

For the foundation with a volume of 1.54 m³ you need 118 bags of 25 kg or 74 bags of 40 kg of concrete, rounded up.

Note:

The rule of thumb above is an average value. Since different concrete and screed mixtures have different ratios of “dry” to “mixed”, you should always follow the packaging instructions and, if you are unsure, ask the dealer’s specialist staff for advice.

Depending on the quantity required and the current price development for building materials, it may be more cost-effective to mix the concrete yourself from cement, gravel or sand and water instead of using the finished concrete mixes. For very large quantities, it may be worthwhile to have ready-to-pour concrete delivered. Comparative offers should be obtained here in individual cases.