- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

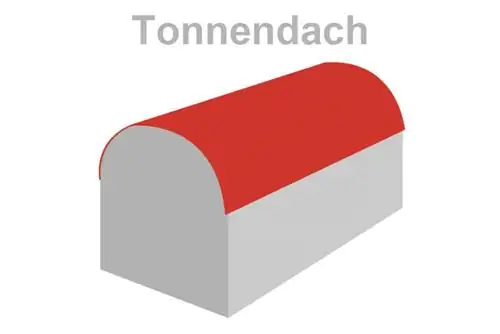

The arched shape of the barrel roof can only be found on a few residential buildings in our region. But technical progress and the courage to try something new are ensuring that this unusual roof construction is becoming increasingly popular. The advantages and disadvantages are explained below, as well as general information about the barrel roof to help you understand its structure and the technical constraints.

The Barrel Roof

Originally, the barrel roof was known primarily from the area of sacred buildings, where brick barrel vaults marked the first step from the flat ceiling to the filigree and at the same time highly complex structures of the Gothic period. In the age of industrialization, this roof, which could be realized in a large span and at the same time of almost any length, conquered the industrial and traffic building sector. It was only as part of classical modernism in the 1920s that the barrel roof made its way into the world of residential buildings through the use of steel structures and new, clear building shapes. Rarely found in postmodernism, the barrel roof is not experiencing a real renaissance today, but it still provides striking shapes and at the same time easily usable interior spaces in individually planned residential buildings.

Construction and statics of the barrel roof

Earlier barrel roofs were usually created in the form of a classic, brick arched construction. This enabled the load to be transferred to the load-bearing external walls below via the curved surface made of stone or brick and mortar without any weak points. In order to absorb the outward pressure of the arch construction, the walls were usually stabilized on the outside using extensions or stiffening transverse walls.

Modern barrel roof, on the other hand, generally corresponds statically to what was developed in the context of industrialization and is still used unchanged today in terms of load transfer. Static elements of the modern barrel roof are:

- Radially curved arch supports made of steel or wood

- Flat covering as a base for roof construction, usually made of wooden formwork or sheet metal

- Stiffening cross connections between the beams, often designed as a tension cross (“St. Andrew’s Cross”)

- Tension band between the lower support points of the arch supports to absorb the shear forces at the base of the arch

NOTE:

Not every single arch supporter has to be secured with a drawstring. For short buildings, the concrete ring anchors of the gable walls or a few tension straps, which can be hidden invisibly in the interior walls, may be sufficient.

Roof structures for barrel roofs

Although the barrel roof is quite similar to the rafter roof in terms of the static structure of beams, it differs fundamentally in the structural structure of the roof. Due to the curvature of the roof surface, insulation between rafters and cladding on the soffit are possible, but are usually extremely complex and therefore financially unprofitable. Instead, a roof structure for the barrel roof has become established today:

Sandwich roof

- Arch supports visible in the interior

- Sandwich element prefabricated and adapted to the curvature of the support, consisting of a lower support shell, polystyrene insulation and a top layer as weather protection and water-conducting layer

- Top and bottom sheet metal, usually titanium zinc or aluminum

ATTENTION:

Since these sandwich elements, which originally come from industrial construction, cannot be bent, the individual segments must be prefabricated to size.

It is much rarer for a barrel roof to be constructed as a wooden structure:

- Flat formwork as an internally visible covering on arched beams

- Vapor diffusion-tight layer on formwork, usually foil

- Beams running across the arch on formwork, insulated with mineral wool that can be flexibly adapted to the curve of the roof

- Roof covering made of pre-formed sheet metal parts, if necessary on a batten substructure

NOTE:

Since a classic counter batten running from eaves to ridge is not possible with a barrel roof due to the curvature of the roof, non-ventilated sheet metal roofs are usually used here. Depending on the system used, the membrane that prevents steam from entering the interior can then be made semi-bermeable so that any moisture in the insulation can still be released inside.

Special barrel roof shapes

For economic reasons, there are various shapes of barrel roofs that deviate from the real, continuously rounded arch:

Segment roof

- Dissolution of the arc into a polygon with several straight sections

- Structure like a straight roof surface is possible here, but transition points between the roof segments are required, therefore a high number of detail points

- Also suitable for tile roofing under certain conditions

" fake" barrel roof with ridge

- Formation of a ridge with arched roof surfaces on both sides

- Suitable for rear-ventilated constructions, as air can escape at the ridge point

- Mostly slightly pointed shape different from real bow

- Certainly alternative roof coverings to sheet metal are possible, as the roof curvature is much smaller

Roof pitch or rounding

The curved shape of the barrel roof results in the lack of a uniform roof pitch. Instead, every barrel roof, regardless of the arch radius, always has a particularly steep slope at the base and an almost non-existent slope at the apex. Not every barrel roof necessarily has to consist of a semicircle. Differently selected arch segments can range from the familiar dome shape to a merely flat slope with an upward curvature.

Roof structures in barrel roofs

Dormers, cross gables and roof balconies can be created equally well with the barrel roof. Thanks to the common sheet metal covering, transition points between the structure and the roof cladding can be solved quite easily. The quite steep incline at the base of the complete semicircular arch even makes it possible to use “normal” facade windows in the barrel roof to a certain extent. The usability of the roof space is therefore significantly increased compared to other roof shapes.

Costs

Due to a very limited selection of materials and a high level of individually manufactured components, the barrel roof is considered an expensive roof shape. Although it also offers numerous advantages, none of these are to be found in the area of cost reduction and high usability of “off-the-shelf” series products. It can therefore be seen that, from a cost perspective, the barrel roof is clearly in the area of individually planned individual buildings and is unlikely to be used in the creation of affordable living space.

Advantages and disadvantages

As is clear from the previous explanations, the rather unusual shape of the barrel roof has some elementary advantages, which, however, come with weaknesses that should not be neglected:

Advantages

- Optimal ratio of envelope area to created space

- The rooms are easy to use due to the high incline at the base of the barrel (almost vertical walls)

- Statically effective supporting structure due to arch shape without real field center

- With sheet metal roofing, no weak points in the form of transitions or ridge details

- Modern construction and design options

Disadvantages

- No classic structural design can be implemented

- Economical support structure limited to steel or wood, but wood is quite expensive due to the manufacturing effort of the arch supports

- Limited selection of possible roof coverings

- High effort and precise planning required for prefabrication of the roof elements

- high costs