- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-06-01 06:48.

In order to save money when building a house, some builders decide to lay the sewer pipes themselves. However, the type of pipes, the slope at which they are laid, as well as the angles and connections must meet certain requirements. Interested do-it-yourselfers will find out below what is important and how the pipes have to be laid and connected.

HT or KG sewer pipe - the differences

Sewer pipes are available in different designs. On the one hand, the HT pipes (high temperature pipes). They are gray and made of PP (polypropylene) plastic and are designed for the sewage pipes within the house. They can have diameters of 40, 50, 75 and 110 millimeters, with the different diameters designed for different uses.

For the sink, for example, a diameter of 40 millimeters is sufficient. For the toilet, however, it must be 110 millimeters.

The KG pipes (sewer base pipes) are orange-brown and designed for wastewater drainage outside. So you connect the house's pipes to the sewer system. KG pipes are laid underground and are available with diameters of 110 and 125 millimeters. So only KG pipes are suitable for connecting the house to the sewer system.

Reinforced KG pipes as a special shape

They are usually green rather than orange-brown and are designed for use in high-traffic areas. For example, they are used in places where cars are often parked. When selecting and planning, more heavily polluted areas on the property should also be taken into account.

Planning and requirements

Before laying the sewer pipe, the route must first be planned. Which pipes are used depends on the local regulations and the circumstances. In order to avoid mistakes, laypeople and hobby craftsmen should inform themselves about the applicable regulations in advance.

In general, however, the following points apply:

Trench Depth

The sewer pipe is laid at a depth of 100 centimeters. The trench must therefore have an appropriate depth. An exception are more heavily polluted areas, for example where there is a lot of traffic. Here the trenches must be 150 centimeters deep.

Gradient

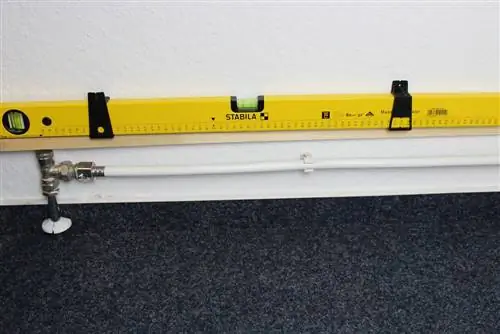

The pipes must be laid with a gradient of one to two percent. This means that a gradient of one to two centimeters must be planned for every meter of pipe length. With a total installation length of 50 meters, there must be a gradient of 50 to 100 centimeters. This must also be taken into account when creating the trench.

filling material

To protect the pipes, they must be laid on sand and initially covered with sand. On the one hand, this measure ensures that gravel and sharp stones cannot cause damage to the sewage pipes. The sand layer also ensures better pressure distribution.

Angle

For changes in direction, only arcs with an angle between 15 and 45 degrees may be used. Only bends with 45 degrees can be used for branches.

load

If the sewer pipes are laid under a parking lot or another heavily trafficked area, reinforced KG pipes must be used. However, the normal KG pipes are sufficient for other areas.

Preparation

So that the wastewater pipes can be laid easily afterwards, appropriate preparation is required after planning. This includes the following steps:

- Dig a trench, taking the necessary gradient into account. The trench should be wide enough so that the pipe can be easily aligned in the middle.

- Remove stones and roots from the ditch.

- Compact the soil in the trench.

To ensure that the slope is correctly created, you should measure again carefully after compacting the soil.

Tip:

Due to the depth of the trench required, it is very time-consuming to dig it by hand. It is therefore worth renting a mini excavator.

Laying sewer pipes

Once the preparations have been completed, the subsequent laying and connecting of the pipes is comparatively easy. All you need to take into account are the following steps:

- Cover the bottom of the trench with a ten centimeter thick layer of sand. This serves to protect the floor.

- The installation begins at the lowest point of the gradient so that the sleeves point against the direction of flow of the wastewater.

- The first pipe is inserted and connected to the second pipe by pushing it into the connection. It is helpful to use an appropriate lubricant as it makes it easier to slide over the rubber seal. The two pipes are attached to each other using pipe clamps.

- The pipes are aligned in the middle of the trench and covered with sand up to a trench height of 30 centimeters each.

- The sand layer is compacted - but only by hand. Under no circumstances should heavy equipment be used here, as this could damage the pipes.

- The soil is applied in layers and, like the sand, compacted by hand. An appropriate device for compaction may only be used from one meter above the pipe.

Cut pipes

For the outside sewer pipe, it may be necessary to shorten individual sewer pipes. Since the edges of the original pipes are beveled on the outside and inside to make it easier to slide into the socket, the customized shortening involves more than just sawing.

- The pipes are measured and the cut edges are marked. In order to make a straight cut, several marks should be measured and placed on the pipe using a ruler and a pen and only then connected together.

- The pipe is placed on a table so that the excess pipe piece protrudes above the table.

- The pipe is shortened at the marked point using a saw.

- The cut edge is chamfered inside and outside with a file.

- The cut edges are smoothed with sandpaper so that there is no damage to the rubber seal of the connecting part.

Even after cutting, filing and smoothing, lubricant should be used on the connections to make it easier to insert them into the connecting elements of the pipe system.