- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

Concrete with improved flowability is known as flow concrete. Conventional concrete is mixed with superplasticizers. This improves certain properties so that the concrete can be used for specific applications.

Composition

What is fluid concrete? This question often comes up when looking for the right type of concrete for your own project. This type is classic concrete that is mixed with a special plasticizer. The plasticizer makes the otherwise viscous concrete significantly more liquid and is easier to pour. There are a variety of plasticizers that are suitable for mixing. These are not individual substances, but rather finished products that are mixed together with the classic concrete, which consists of the following ingredients:

- Cement

- Aggregate

- Water

Fluent

The superplasticizer is usually dosed according to the manufacturer's instructions. The most common assumption is an amount of 0.2 to three percent. Anything more would result in concrete that is significantly too liquid and difficult to process. The use of superplasticizers is suitable for all consistency classes from F1 to F6, which makes flowable concrete quite versatile. Classes F4 to F6, which belong to the flowable classes, are most often prepared with superplasticizers. There are different basic materials that are used to produce superplasticizers. The main difference between them is their effectiveness. The most important ones include:

- Naphthalene sulfonate: often used raw material

- Lignin sulfonate: often used with other raw materials

- Polycarboxylate ether: for high performance plasticizers

Note:

Adding superplasticizer to the required consistency is called “adjusting”.

Features

Due to their composition, fluid concretes have special properties that no other types can offer. For this reason, they are highly specialized concretes whose primary property is flowability. In comparison, the concrete is significantly more fluid and softer, making the mixture easier to pour. At the same time, this type is self-compacting concrete because it spreads faster regardless of the quantity used. The other properties of flowing concrete depend on the starting concrete. This means that the following points are determined by the concrete to which the superplasticizer is added:

- Shrinkage behavior

- Crawling behavior

- final strength

Applications

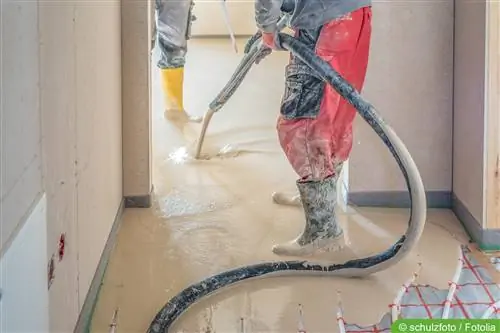

Due to its composition, flowing concrete is much better suited for certain areas of application than other types of concrete. It is most often used to fill formwork stones. The reason: Due to its consistency, the entire stone can be filled easily without any cavities forming in individual areas, which could have a negative impact on the statics of the finished wall. Furthermore, the concrete is easy to pump, which speeds up filling. In addition to backfilling, there are other applications for which flowing concrete is suitable:

- Exposed concrete

- seamless floor coverings

- Floor repairs

- Pouring step or countertops

Compared to conventional types of concrete, flowing concrete can also be used excellently as leveling concrete. They can be used, for example, to increase areas step by step without using too much material. There are just a few points to consider:

- ideal for small areas

- can be used in small quantities

- cure each layer

Tip:

You can also use flowing concrete for artistic purposes. For example, the concrete can be poured into molds and, after hardening, the mixture forms the basis of a sculpture.

Advantages

Floating concretes have a number of advantages in direct comparison, which are primarily used in the applications mentioned. One of the biggest advantages is that it is easy to use with or without a pump, as this reduces the amount of work required. A point that is often overlooked is the lower water consumption while maintaining the same strength. The superplasticizer means that less water is required for mixing, which protects against problems with mixing and concrete that is too thin. Too much water should never be added, otherwise the concrete will lose stability. Since flowable concrete is self-compacting, there is no need for another step. At the same time, less concrete is required because the effective spreading means that smaller amounts of concrete fill more space. You can take advantage of this when pouring surfaces or filling formwork stones.

Note:

The only disadvantage of flowing concrete is the greater planning effort before pouring the mass. For example, formwork blocks must fit exactly so that the concrete does not harden incorrectly or leak.

Costs

When using fluid concrete, the costs must of course be taken into account. In addition to the actual costs for the concrete, there is also the plasticizer, which increases the price accordingly. Since only a small amount of superplasticizer is required per kilogram of concrete, the products are offered in bottles or canisters that are easy to dose. The following costs are price ranges for the superplasticizer:

- 1 l bottle: 7 to 15 euros

- 5 l canister: 10 to 30 euros

If you want to calculate the price for the concrete including superplasticizer, you must follow the dosage recommendation already mentioned. Concrete is available in different grades, which has a significant impact on the price. For example, if you want to mix a cubic meter of concrete with class C30/37, you have to calculate the amount of superplasticizer required:

- 1 m³ of concrete corresponds to 1,000 l

- 0, 2 to 3% superplasticizer is 2 to 30 l

So you need two to 30 liters of superplasticizer, which corresponds to a price of around 12 to 200 euros, depending on how much of the additive is needed. This means the final cost for one cubic meter of C30/37 concrete is as follows:

- 1 m³ concrete: 90 euros

- 0, 2 to 3% superplasticizer: 12 to 200 euros

- Floating concrete: 102 to 290 euros