- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

The term “dry time” is not in itself applicable to concrete, because strictly speaking it is the so-called setting. A chemical process of crystallization. This can last for several years.

Drying

The term drying only applies to a limited extent to concrete. This is because the material does not harden as moisture escapes. In fact, concrete always contains a certain amount of residual moisture. Although the water evaporates, hardening occurs through crystallization or so-called setting. The thicker the concrete layer, the longer this chemical process takes.

The escape of water depends on various factors. These include:

- the temperature

- the surrounding earth moisture

- humidity

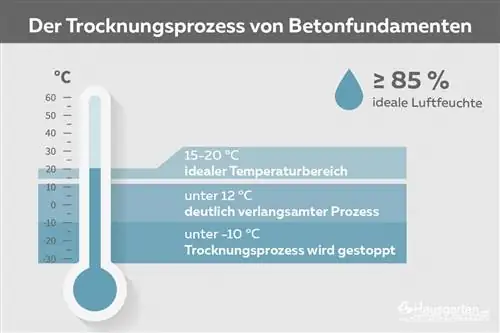

If the weather and environment are dry and warm, setting takes place faster. At less than 12°C the process is significantly slowed down. If the temperature is below -10°C, it will stop completely. It therefore makes sense to have the foundation watered as early as possible in the year, as soon as the temperatures are above 12°C. The ideal temperature range is between 15 and 20°C. In addition, late frost should no longer be expected. This allows it to set well over the summer and the duration is shortened.

However, it should not be warmer than 30°C immediately after application, as temperatures that are too high can cause stress cracks in the surface of the foundation. It is also ideal if light rain falls in the days after watering. This keeps the surface moist and reduces the effort required for post-treatment.

Minimum load capacity

After pouring the concrete, you must wait at least 28 days before the foundation can be worked on again and loaded for the first time. Even then, it cannot be expected that it will be completely dry.

This requires at least several months. In very moist soil, or in cold and rainy areas, drying and hardening can even take several years.

Speed up drying

It is possible to accelerate the hardening of concrete by adding admixtures or using alternatives. These are, for example, mineral compounds that accelerate drying or setting.

Calcium

Possible additives include calcium chloride or calcium nitrate. These are catalysts that are used for the crystallization processes. They are cheap and easy to use, but not suitable for every use. If they come into contact with steel, they cause corrosion. They must therefore not be used in conjunction with steel beams or mounting iron. However, there are also non-corrosive calcium compounds, although they are usually more expensive. The admixtures are added to the water before the concrete is mixed.

Note:

Concrete poured in difficult, cool and damp areas can harden significantly faster. This can also prevent moisture from remaining for too long and mold from forming.

Seed Crystals

So-called C-S-H germs can also accelerate the hardening of the concrete foundation and can be added directly to the mixture. Like the calcium compounds, they act as catalysts. The C-S-H seeds are also known as seed crystals and ensure faster setting. The application is extremely simple. The product is only added according to the manufacturer's instructions. However, products with seed crystals are generally comparatively expensive. The use is often not worthwhile, especially in dry areas.

Quick concrete

Another alternative to the long drying times and sometimes tedious setting of normal concrete, quick-release concrete can also be used. This contains binders and catalysts. This means that setting times of half an hour can be achieved. However, with rapid concreting, complete hardening only occurs after several weeks to months. However, it can be charged within a shorter period of time. However, a potential disadvantage is that quick-mix concrete is only suitable for smaller areas, blocks and lighter foundations. For example, for the foundations of:

- Garages

- Shed

- small workshops

It can also be used for other areas, including:

- concreting driveways

- setting playground equipment or arches in concrete

- Making bases

- Creating root barriers and lawn edges

- create little-used sidewalks

- repairing and renovating stairs

Pouring an entire house foundation with quick-release concrete is not recommended, as it is often less resilient than concrete.

Aftercare: Aids & Advice

Anyone who pours a concrete foundation usually wants to achieve a short drying time and a quick minimum load capacity. Nevertheless, post-treatment is necessary to ensure that the quality of the concrete is as high as possible and that no cracks form or the material shrinks. To do this, you need to pay particular attention to two factors: temperature and humidity.

The optimal temperature is 15 to 20°C and a humidity of 85 percent or more. If freezing temperatures occur, a heating cannon can be used to ensure that the fresh concrete is not damaged by the frost. If the temperature rises above 30°C and the humidity is very low, the foundation should either be constantly moistened or covered with a vapor-impermeable film to keep it moist. This prevents the surface from drying out too quickly and cracks from forming due to the tension that occurs.

ATTENTION:

However, it is important that the film does not lie directly on the fresh concrete. Otherwise, unsightly and uneven discoloration could occur. The cover is therefore stretched over the concrete and formwork in such a way that it reduces evaporation but does not come into contact with the foundation.