- Author admin caroline@plants-knowledge.com.

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

For pumps, the direction of flow is crucial for reliable function. A check valve can ensure the correct direction and thus serves as additional or necessary safety. But how is it installed?

Operating principle of the check valve

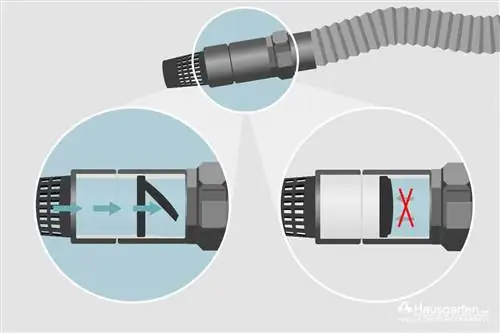

A check valve is a component that connects hoses or pipes and can therefore be used between different components. Water or gas flows through the valve. However, inside it has a flap that seals the opening in the opposite direction of the desired flow as soon as it is exposed to pressure.

For example, the medium can flow back from right to left but not from left to right. The same applies in the vertical direction. If a liquid has to be pumped from bottom to top, the valve prevents downward flow. This makes it possible, among other things, to set the pump lower.

Vertical installation

As a rule, check valves are installed vertically in the following cases:

- Garden Pumps

- Heating pumps

- on washing machine drains

- Well pumps for pumping water

- Pond pumps

It is important in any case that a suitable valve is used for vertical installation. Not every model is suitable for this.

The installation must also be carried out correctly. The direction and the connecting pieces are crucial here. The respective intended use must also be taken into account. If it is a matter of maintaining a water column, the water must not flow back down and out of the hose.

However, if backflow into the pump needs to be avoided, the valve must be installed after dispensing.

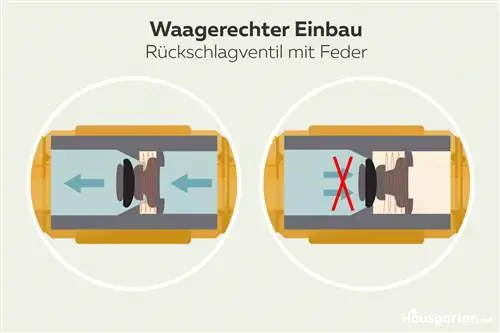

Horizontal installation

In some cases it cannot be prevented that the valve has to be installed horizontally. This applies, for example, if there is little or no difference in height or if there is no appropriate space.

These include, among others:

- longer cables

- higher drains

- Connections between pumps and larger vessels

Horizontal installation can only be done with models designed for this purpose. You usually need a spring as additional equipment in order to ensure a really tight seal and thus prevent backflow.

This is what you need to pay attention to when making your selection.

Tip:

An alternative to this is the angled design. It is widespread and combines both a vertical and horizontal course.

note direction

Check valves always have an arrow that indicates the direction of flow of the water or gas. Typically, the arrow must point away from the pump to prevent water from flowing back. This applies, among other things, to washing machines if a check valve is installed between the hose and the drain pipe.

It can look different if water is sucked in and a column is to be created. This often makes sense for larger delivery depths. Here the arrow must point to the pump so that the water can be drawn in more easily and safely. It then no longer flows out of the hose because it is stopped in stages. This also prevents air from being drawn in.

Tip:

The connection to the hoses and the type of hoses are just as important as the valve itself and the direction of flow. A vacuum must be able to be created in the hose, which means that the seals also play a major role.

Make the right choice

On the one hand, it is important that the valve is designed for the flow direction or the mounting direction. These can be found both in hardware stores and online. You can usually find a much larger selection online. There are also more comprehensive descriptions here and the search is easier.

The following are important when making a purchase decision:

- Mounting direction, horizontal or vertical

- Valve design, straight or curved or shaped as an angle

- Integrated spring

- Port size

- Material

A targeted search in the hardware store is often not as easy as on the Internet. Therefore, purchasing here is particularly recommended if you do not yet have extensive experience with check valves.

Tip:

High-quality metal valves are slightly more expensive to purchase, but are more durable and have a longer service life.

Perform maintenance

It's not just the mounting direction and the features that are important when selecting the check valve. Since the valves need to be serviced regularly and may need to be flushed or even replaced, they also need to be easy to access.

They should therefore always be installed in such a way that checking is easy. A quick and easy removal should not be in favor of the density.