- Author admin [email protected].

- Public 2023-12-17 03:39.

- Last modified 2025-01-24 12:45.

Sandstone is a common building material in Germany that has been used since ancient times. There are good reasons to stick with this tradition, because sandstone is also a very beautiful building material, and the sandstone wall is one of the most durable garden structures that you can easily build and grout yourself. Even in two different versions, for which there are instructions below:

Foundation or no foundation?

This is the first question that must be decided before building the wall, followed by decision-making aid and instructions for creating a strip foundation:

- A sandstone wall in which the stones are properly walled with mortar should be placed on a frost-free foundation

- A wall with a supporting function, at the bottom of a slope e.g. B., where the ground is located, needs a foundation for safety reasons

- If a sandstone wall is not to experience any heaving or settling, even in severe frost, it is better to rely on a foundation

- If the sandstone wall is to be built on an existing smooth concrete surface, this is easily possible if it stands on a standard substructure made of a vibrated gravel and chippings bed

- If not, it depends on the height of the sandstone wall, really powerful walls should not be placed on an unpaved concrete surface, they will crumble at some point

- Especially not if water could collect, which quickly becomes noticeable if a gravel foundation is missing as a capillary-breaking frost protection layer

- As soon as the lower wall stones are “in a tub of water” in frost, they will simply burst

- Then you can create a capillary-breaking layer with a border and drain on the concrete or place the sandstone wall somewhere else

- If you just want a simple small sandstone wall as a garden decoration, you don't need a frost-free foundation, but can simply build the wall on a 30 to 40 cm thick layer of gravel or gravel

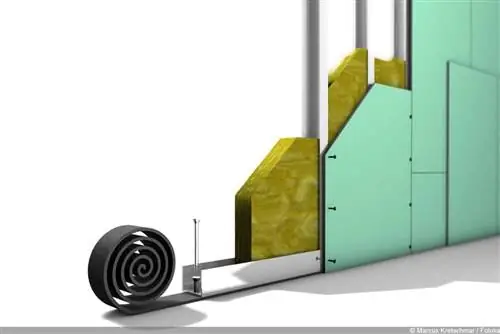

The frost-free strip foundation

A frost-free strip foundation is created like this:

- Mark the base of the wall + allowance of at least 10 cm on all sides (depends on the height of the wall) + thickness of the formwork with a batter board

- A batter board is a simple construct made from masonry line and wooden pegs

- This strip for the foundation is now excavated to a depth of 75 cm

- For a long time, a depth of 80 cm was the measure of frost resistance, warming due to climate change is already changing the standard specifications here

- When the foundation trench is finished, a gravel bed is placed on the ground as a so-called clean layer

- This is then compacted with a vibrating plate and, if necessary, covered with PE film

- Now the formwork is installed and, if necessary, reinforcement is laid out on the ground

- The upper edge of the formwork is aligned horizontally, now the concrete can be filled in for the foundation

- You need concrete of strength class C12/15

- For small foundations of tiny walls, the concrete can be mixed by hand:

- For example in a wheelbarrow, ideally made from ready-mixed concrete that only needs to be mixed with water

- Concrete for larger foundations is mixed on site with the concrete mixer (first sand and cement, then water) or delivered directly from the concrete factory

- It must be distributed evenly in the formwork, occasionally poking the mass with a shovel to avoid air pockets

- Once the concrete is in the formwork, it is compacted with a tamper and, if necessary, topped up a bit

- The concrete is then pulled off smoothly and covered with foil/tarpaulin. After drying, the formwork is removed

- If you did the work yourself, tools and concrete mixers must be cleaned immediately with water

- Make sure that no concrete residue gets into any sewer pipes, which will become blocked immediately

- Caution is advised when skin comes into contact with concrete, it irritates the skin

Instructions: Building a sandstone wall

First all the ingredients are put together:

- Mason's hammer

- Mason's Trowel

- Mortar compound, ready mixed, for beginners also as ready-made dry mortar that can only be mixed with water

- Guideline

- Sandstones

- Plumb bob

- Spirit level

- Inch rule

Now let's start building walls:

- Apply a thick layer of mortar to the foundation

- For sandstone you need a very special mortar, see below

- The first row of sandstones is lined up on the mortar

- And aligned precisely with a spirit level, folding rule, mason's hammer and ruler

- Joints of around one centimeter are left between the sandstones

- Between the rows upwards too

- It is important that the first row is straight so that the entire wall does not become more and more slate towards the top

- If you build walls in the classic stretcher bond, the next row of sandstones is always placed half offset

- You can first pull up the side walls

- Similar to building up a staircase, at the bottom 4, then 3, 5, then 2, 1, 5 sandstones left and right

- Now you can build higher walls in between, with sandstones at equal distances that sit as precisely as possible on one level

- A spirit level and plumb bob should be used every now and then, even if the wall looks nice and straight

- A little mortar may ooze out of the sides of the base plate and the joints

- Then you don't need to pay attention to the beauty of the joints from time to time

- The stones are “saturated” and fully bonded with mortar

- With this method you have to scrape out the joints every now and then by around 1.5 cm

- When the wall is up (and you have taken a break), grout the open 1.5 cm calmly, carefully, evenly and clearly to see

Mortar for the sandstone wall

An “iron basic law of bricklaying” is: The mortar must be softer than the stone used. Many natural stone mortars become too hard after setting for the very soft sandstone. If you use a mortar that is too hard, this will have long-term consequences: If the weather takes a toll on your wall, it will not be absorbed by the mortar, as would normally be the case, but the beautiful, soft, already sensitive sandstone will be directly affected. It then weathers much faster than would normally be the case.

So don't use “just any mortar”, even the frequently recommended trass mortar leads water to the soft sandstone and is not suitable. Rather, sandstone should only be installed with so-called NHL mortar, which is a mortar with natural hydraulic lime. Alternatively (because it is not as authentic) you can use HL mortar, which is chemically identical but more uniform, it is a fine lime mortar made from hydraulic binder phases (cement + hydrated lime). However, the air lime mortar that is often available today is not suitable; it has been shown that it suffers relatively quickly when used outdoors. For new sandstone walls with standard joints, a grain size of around 2 mm is recommended.

A very special wall

A very special wall is the dry stone wall made of sandstone, a wall that is stacked completely without any binder. Dry stone walls have a long tradition here, as Germany is rich in sandstone. From Buntsandstein, Burgsandstein, Kalksandstein, Schilfsandstein and Stubensandstein, each region has its own sandstone to offer, in a greenish color (Abtswinder + Sander sandstone) or yellowish-brown to brown (Ibbenbürener sandstone, Ruhr sandstone), for example. Bentheim sandstone is light gray to white, Dietenhan sandstone, Seedorf sandstone, red Wesers sandstone are red, sandstone was used in many old buildings and in many dry stone walls. Traditional gardening is currently back in fashion because it brings more nature into the garden. Sandstone dry stone walls are not only ecologically and biologically valuable, but also incredibly durable if they are built correctly. They become small biotopes in whose cracks and crevices (already rare) small animals such as amphibians or wild bees live. Correctly building a dry wall made of sandstone is fun in itself and is more like a puzzle than classic wall building with wet and skin-irritating mortar. A beautiful sandstone dry stone wall requires some planning, but it's worth it.

Foundation for the dry stone wall made of sandstone

Classic dry stone walls are placed on a dry foundation made of gravel or crushed stone, around 10 cm wider on both sides than the bottom row of the masonry. How to proceed:

- You need gravel or gravel grain size 0/32 - 0/45, building sand, sandstone for the wall base

- Dig a trench 30 to 40 cm deep for the foundation, store the excavated material nearby

- The trench should be 10-15 cm wider than the base of the wall and 5-10 cm wider than the side walls

- If water has to drain, you must create an incline in the direction of drainage

- The trench is filled two thirds with gravel/gravel, this layer is then very carefully compacted

- This works with a tamper and a lot of force and best of all with a mechanical vibrator

- A layer of building sand is placed on top of this, 5 to 10 cm up to the edge, which is then removed smoothly (with a simple board, for example)

- The large, heavy stones for the wall base are laid; they should (and will) press a few centimeters into the sand bed

- Leave joints of around 2 cm wide between the individual stones

- These joints and are filled with earth from the excavation

Dry stone wall made of sandstone

Now the sandstone dry stone wall can be stacked:

- The heaviest chunks have been processed into the wall base, now the remaining stones are sorted by size

- In decreasing size for the wall, a few particularly beautiful, preferably slightly elongated stones for the top of the wall

- A pile of small stones is stored specially; they are used to wedge gaps

- You can support the settlement of wild animals through planting, which also looks very decorative

- Every rock garden plant, many perennials and a number of grasses can be planted in the sandstone wall

- If the excavation for the foundation is topsoil, you can fill it straight away

- Otherwise other soil should be ready

- The plants must also be selected and prepared in advance, sorted by wall base, joints, wall crown

- Planting is also strongly recommended because it stabilizes the dry stone wall

- Even considerably, otherwise it is only held together by its own weight and the tilting of the stones

- Now put some topsoil and the corresponding plants on the first row of stones

- Then the pre-sorted stones are gradually stacked with evenly spaced joints

- In between, always fill in soil and plant plants

- Quietly lots of earth, as the height increases it becomes compacted by the weight of the stones

- Where stones are “shaky”, wedge small stones between them until everything is firmly in place

- When your stone puzzle is finished, the wall crown is placed

- Make sure the height is even and the gaps are wide so that plenty of soil/plants can fit in them

That was the construction at a glance, a dry stone wall can grow straight upwards, but then needs a static calculation once it reaches a certain height, or is classically built around three times as high as it is wide, with a massive base of at least 40 cm and up to 20% narrower towards the top, on both sides. Always remember that sandstone is a soft and sensitive material that needs to be treated with care when cleaning and would prefer to see nothing other than water and a brush with possibly a little soft soap, especially neither chemicals nor acidic household cleaners.

Conclusion

Natural dry stone walls made of sandstone are particularly trendy, but sandstone is actually a great building material. However, it is also a very soft building material, and you should be well informed about its processing and treatment if you want your sandstone wall to last a long time and look beautiful.